Wood Hammer Mill for Sale

1.Stable Operation

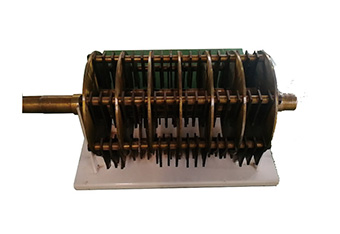

The crusher's rotor is dynamically balanced before assembly, ensuring smooth running. This reduces vibrations and boosts reliability, minimizing breakdown risks.

2.Durable Hammer Blades

Made of manganese steel and strengthened with wear - resistant alloy, the hammer blades last longer. Fewer replacements mean lower overall maintenance costs.

3.Easy Maintenance

With operating doors on both sides, the crusher allows for quick access. This makes maintenance simple, especially when replacing screens, and boosts operational efficiency.

4.Efficient Screening and Dust Filtration

The two - piece screen offers 360 - degree discharge for better screening. The customizable two - stage Shaklon filtration effectively removes dust, adapting to different work conditions.

5.Model Versatility

There are various crusher models, with output capacities from 1 to 15 tons per hour. This wide range meets different production needs, whether for small or large - scale operations.

The introduction of Wood Hammer Mill

A full pulverizer set consists of the pulverizer main unit, fan, saxophone - shaped component, shut - off fan, dust bag, and other elements. Before assembly, the key components of the pulverizer, especially the rotor, are subjected to dynamic balance calibration. This is done to guarantee the stable running of the machine. Moreover, the motor base assembly platform and the rotor spindle bearing seat assembly platform are machined synchronously in one operation by a large - scale CNC machine tool. Such precision work ensures the smooth operation and the highest level of accuracy of the machine.

High - efficiency crushers find extensive application in the biomass energy and feed processing sectors. This apparatus is capable of crushing a wide range of raw materials, such as: Wood: pine, poplar, fir, bamboo, branches, bark, wood chips, shavings, etc. Straw: corn straw, wheat straw, rice straw, rice husks, peanut shells, cotton stalks, etc.

Model | Power(KW) | Capacity(T/H) | Notes |

JLFS65*130 | 132 | 5-6 | Suitable material: length<5cm, width<5cm, thickness<0.5cm |

JLFS1000-1600 | 75 | 8-10 | Suitable material: length<5cm, width<5cm, thickness<0.5cm |

JLFS1200-1300 | 132 | 10-15 | Suitable material: length<5cm, width<5cm, thickness<0.5cm |

The primary wearing and replaceable parts of the hammer mill are as follows:

1. Hammers

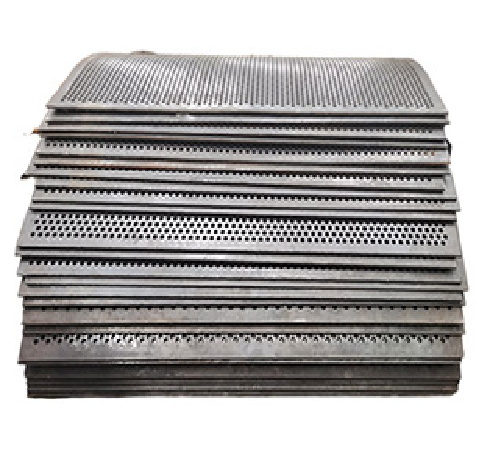

2. Screen Mesh

3. Rotor

Company Profile

We are deeply convinced that quality and efficiency form the bedrock upon which an enterprise can establish itself, and that service and quality are the keys that unlock an enterprise's growth. Our product portfolio consists of wood chip pellet machines, straw pellet machines, biomass pellet machines, sludge briquetting machines, and air flow and drum series drying devices. Also included are cutting and crushing series equipment, as well as a comprehensive set of biomass pellet production line equipment such as other supporting cooling, screening, packaging, and conveying equipment. Our company's technicians will customize and engineer the equipment according to the specific needs of customers and the real - world space available in their factory buildings.