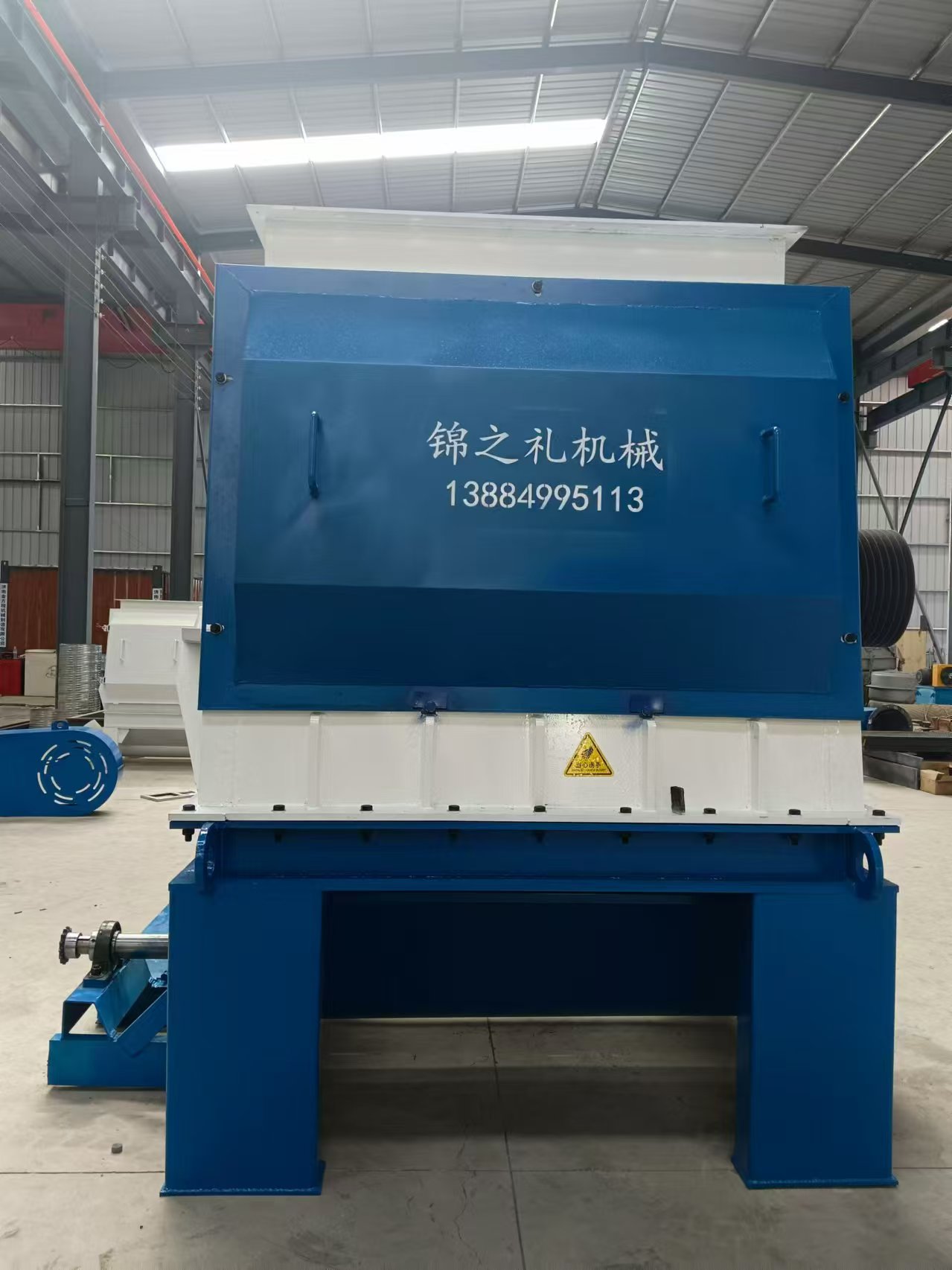

Wood Hammer Mill

Wood Hammer Mill

1.Stable Operation: The crusher’s rotor undergoes dynamic balance calibration before assembly, ensuring smooth and stable operation.

2.Durable Hammer Blades: The manganese steel hammer blades, reinforced with wear-resistant alloy material, extend the blade’s lifespan and reduce overall maintenance costs.

3.Easy Maintenance and Access: Operating doors on both sides of the crusher allow for quick maintenance and easy screen replacement, improving operational efficiency.

4.Efficient Screen and Dust Filtration: The two-piece screen offers 360-degree discharge for improved efficiency, while customizable two-stage Shaklon filtration ensures effective dust removal.

5.Model Versatility: The crusher is available in various models with output capacities ranging from 1 ton to 15 tons per hour, accommodating different production requirements.

The introduction of product

A complete Wood Hammer Mill set includes the pulverizer host, fan, saxophone, shut-off fan, dust bag, and other components. The main parts of the pulverizer, particularly the rotor, undergo dynamic balance calibration before assembly to ensure stable machine operation. Additionally, the motor base assembly platform and rotor spindle bearing seat assembly platform are processed using a large CNC machine tool in a single, synchronous operation. This precision ensures the machine operates smoothly and with optimal accuracy.

Parameter

Model | Power | Yield T/H | Raw Material Situation |

JLFS65*130 | 132kw | 5-6 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

JLFS75*150 | 160/200 | 7-8 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

JLFS1000-1600 | 250kw | 8-10 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

JLFS1200-1300 | 315kw | 10-15 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

Note:According to the model supporting: discharge auger fan, dust collector, Shaklon, air closure, piping, inlet and outlet belts, electric control cabinet. | |||

These products are highly favored both domestically and abroad within the industry. Biomass compression molding equipment, for instance, has been proven to be highly efficient in converting various biomass materials like wood chips and straw into compact fuel pellets, significantly increasing the energy density and facilitating their storage and transportation. This not only promotes the utilization of renewable energy sources but also helps reduce reliance on traditional fossil fuels, making a positive impact on carbon emission reduction goals.

Company Profile

The company's products are mainly related to industry fields such as environmental protection and low - carbon, biomass energy, and urban and rural environmental construction. Its product series consist of biomass compression molding equipment, organic fertilizer equipment, urban and rural garbage treatment equipment, and environmental protection dust removal equipment, among others. These products are highly favored both domestically and abroad within the industry.