Comprehensive Guide to Recycling Wood Scrap & Offcuts: Transforming Waste into High-Value Wood Pellets

In the timber processing, furniture manufacturing, and construction industries, daily production generates vast amounts of wood scrap and offcuts—such as boards, blocks, branches, and construction formwork—often seen as a waste disposal challenge. However, these materials are, in fact, valuable renewable resources. Through advanced processing technologies, they can be transformed into high-value products, achieving a win-win scenario for both the economy and the environment. This article provides an in-depth analysis of the diverse applications for wood scrap and offcuts, with a focus on their industrial-scale conversion into wood pellet fuel, offering global B2B buyers a one-stop solution.

Primary Application Areas for Wood Scrap & Offcuts

Raw Material for the Paper Industry

After crushing and processing, wood scrap can be converted into high-quality pulp, serving as a substitute for virgin wood. This significantly reduces raw material costs for the paper industry and minimizes its environmental footprint.

Manufacture of Wood-Based Panels

As a core raw material for particleboard, MDF, gypsum particleboard, and cement-bonded particleboard, recycled wood substantially increases resource circulation rates and meets the growing demand for green building materials.

Craftsmanship and Creative Products

Wood offcuts, prized for their natural grain, are favored by artisans and can be used to create decorative items, furniture accents, and other niche, high-value goods.

Energy Recovery: Wood Pellets, Charcoal, and By-Products

Through pyrolysis or pelleting processes, wood scrap can be converted into high-energy-density products like wood pellet fuel and charcoal. This process simultaneously yields valuable by-products such as wood vinegar and wood gas, enabling full-component utilization.

Core Advantages of Wood Pellet Fuel Production

Wood pellet fuel is a key enabler in the global transition to clean energy. Its production and utilization provide a scalable pathway for managing wood scrap and offcuts.

High Raw Material Economy

Offcuts generated by lumber mills, furniture factories, and landscaping projects are low-cost and provide a stable supply, drastically reducing raw material expenses for pellet production.

Excellent Energy Performance

Wood pellets can achieve a calorific value of up to 4,500 kcal/kg. Their high density and low ignition temperature make them easy to burn, offering superior combustion efficiency compared to traditional coal. They are suitable for industrial boilers and district heating systems.

Outstanding Environmental Compliance

Combustion emits extremely low levels of sulfur dioxide and nitrogen oxides, with ash content typically below 1%. The resulting ash can be recycled as potash fertilizer. The product complies with international environmental standards such as ENplus and Pellet Gold.

Optimized Logistics and Storage

The standardized pellet form (6-8mm diameter) reduces required storage space by approximately two-thirds. Their uniform shape facilitates containerized shipping, lowering international trade costs.

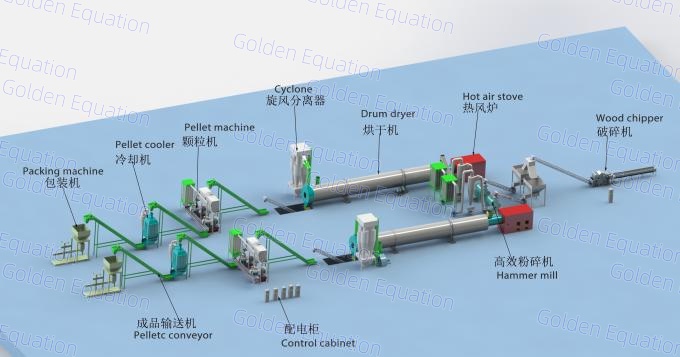

Complete Wood Pellet Production Line Process Breakdown

An efficient wood pellet production line encompasses the following key stages, which can be customized based on client feedstock characteristics and capacity requirements:

Primary Crushing and Screening

Heavy-duty wood chippers reduce large waste pieces to fragments under 30mm. Vibrating screens then remove impurities to ensure feedstock uniformity.

Drying Treatment

Rotary drum dryers precisely reduce material moisture to between 10% and 15%. This is a critical step for ensuring high pellet formation rates and durability.

Fine Grinding and Conditioning

Hammer mills further reduce particle size to under 8mm. Natural binders may be added as necessary to enhance pellet hardness.

Ring-Die Pelleting

The core stage employs ring-die pellet mills made from high-alloy steel. Under high temperature and pressure, wood powder is compacted into dense pellets. Production capacity can be customized from 1 to 10 tons per hour.

Cooling, Screening, and Packaging

Counterflow coolers reduce pellet temperature from approximately 90°C to ambient levels. Double-deck screens then remove fine dust. Final packaging options include bulk bags (ton bags) or 15kg retail bags.

Integrated Dust Removal System

Fully enclosed ductwork, paired with pulse-jet dust collectors, maintains dust concentrations below 10mg/m³, meeting international workplace safety and environmental standards (e.g., OSHA, CE).

Get Your Customized Solution Now!

Company name: Jinan Golden Equation Machinery Manufacturing Co., Ltd

Contact : Yabo

Tel:+85244504801

+8613245411138

Email :biomasspelleteguipment@gmail.com

WhatsApp :+85244504801

Address : Taohuashan lndustrial Park, Xiuhui Town, Zhanggiu District, Jinan City, Shandong Province, China

Download Our Product Brochure: [Pellet Machine_Wood Crusher_Drum Dryer_Hammer Mill_Biomass Pellet Burner-Jinan Golden Equation Machinery Manufacturing Co., Ltd]