1.5-2T/H biomass pellet machine

High Productivity Patented Product

Model Number:XGJ560

Power:90kw,132kw,160kw

Raw Material Proce:Grass, Rice Husk, Wood Sawdust, Biomass, Straw, Cotton Stalks...

Output (kg/h):1500 - 2000 kg/h

Voltage:3phases, 380V ,50hz Dimension(L*W*H):2600x1300x2300mm

Certification:CE, ISO

Place of Origin:Shandong, China

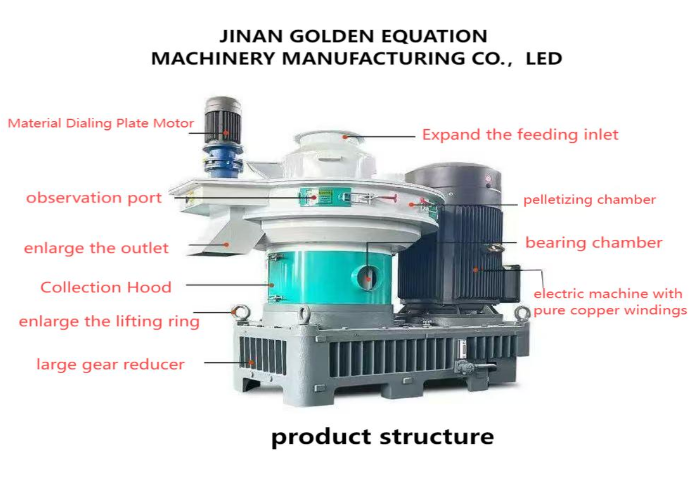

Biomass pellet machine is a kind of pellet equipment commonly used in the biomass energy industry. It is a new type of fuel molding machine that crushes biomass raw materials such as tree branches and straws into rod-shaped particles to replace coal. Biomass pellet machine is divided into flat die machine and ring die machine. The vertical centrifugal high-efficiency ring die biomass pellet machine produced by our company combines the advantages of traditional horizontal ring die and flat die pellet machine, and is especially suitable for biomass pelleting.

Advantages of our biomass pellet machine

1. biomass pellet machine is mainly composed of pellet machine, lubricating oil pump, dust collector and electric control cabinet.

2. The power is 132KW and the capacity is 1.5-2 tons/hour. The motor is directly connected with the gear box to increase the conversion rate of kinetic energy and increase production efficiency.

Technical advantages of biomass pellet machine gearbox

The gearbox adopts a three-stage gear reduction, the carrying capacity is 5 times larger than the old model, and the service life is super long. The gear shaft bearing is an adjustable structure, and the bearing can be adjusted without unloading the machine for a long time-long-term wear and tear. The gearbox is equipped with a lubricating cooling system, which can cool the lubricating oil without stopping the machine, ensuring long-term operation. The gearbox lubrication system is equipped with flow detection and overpressure protection, which can effectively prevent equipment failures caused by poor lubrication.

New feed system

The external setting of the tray completely solves the problem that the tray is easily corroded by high-temperature steam. It is a major innovation of the eighth-generation biomass pellet machine. In the material transfer cover, except for the material transfer turntable, other non-moving parts in contact with materials and steam are made of stainless steel, which fundamentally solves the problem of corrosion of metal materials.

Mould and pressure roller

1. Core component-ring die: using wear-resistant stainless steel material, quenched in a vacuum furnace, the die has uniform hardness, no damage, and super wear-resistant; the die holes are processed by high-speed gun drilling, the holes are evenly arranged, and the inside of the holes is smooth.

2. The core component-roller: the roller adopts super wear-resistant alloy welding technol

Product Attributes

Model No.:GE850 | Brand:GOLDEN EQUATION |

Energy Saving:Energy Saving | Automatic Grade:Semiautomatic |

control mode:Manual control | Warranty:1Year |

Customized:Customized | Spare Parts:Roller Shell+Mould |

Moisture:13%-15% | Application:Press Wood Sawdust Into Pellets |

Motor:Chinese Famous Brand | Pellet Diameter:6-12mm Customizable |

After-sale Service:Engineers are available and they are eligible to apply for visas. | |

Company Profile

The company focuses on cultivating long-term customer relationships, with high quality products and scrupulous dedication to accompany and witness the growth of many of our customers. We firmly believe that there is a market only with quality and a reputation only with service. Quality and efficiency are the fundamentals to win a foothold in the enterprise, and service and reputation are the keys to win the progress of the enterprise.