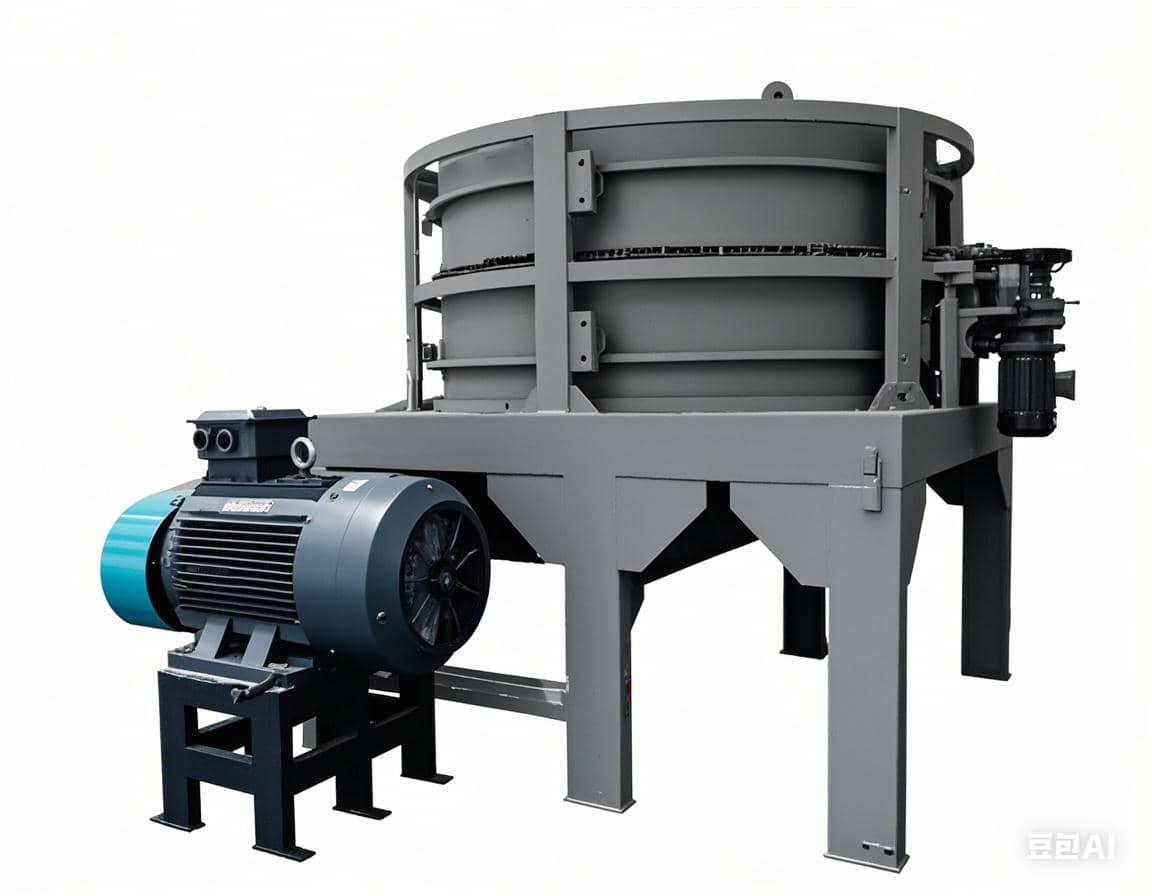

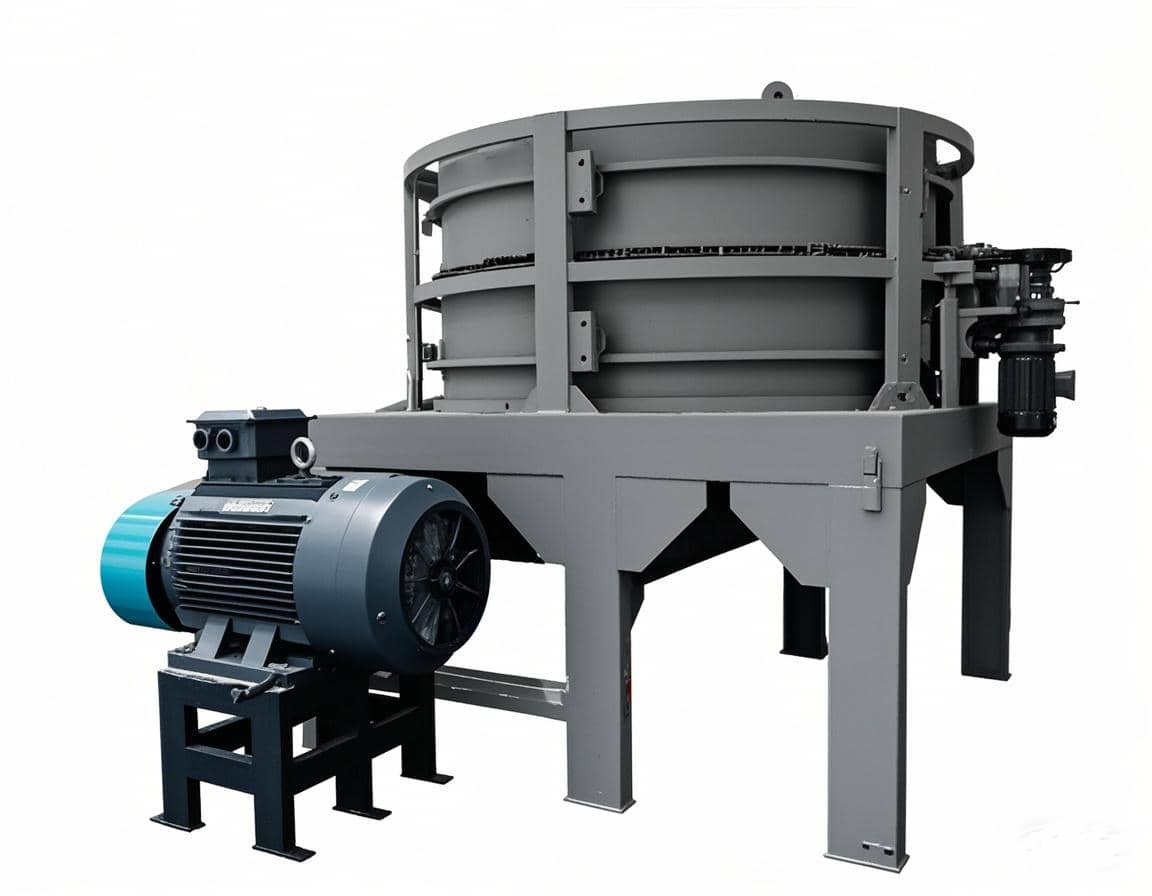

The straw rotary cutting machine is a specialized coarse crushing equipment for processing baled straw materials. Through a high - speed rotor, it can cut baled materials into finished materials with a length of 3 - 5 centimeters. The equipment is compact and reasonably designed, stable in performance and convenient to operate. It is mainly suitable for the crushing treatment of baled materials such as wheat straw, corn straw, rice straw, soybean straw and tobacco stems.

The Rotary Cutting Crusher is a high - performance device, ideal for crushing agricultural and biomass materials. It's mainly composed of a base, gear drive, and rotary box, and can efficiently process straw, logs, etc.

Model | JFC-1600 | JFC-2000 | JFC-2800 |

Power(kw) | 45 | 55 | 90 |

Capacity(t/h) | 1-3 | 3-5 | 5-9 |

Feeding Size(mm) | 1600 | 2000 | 2800 |

Equipment Introduction

The Rotary Cutting and Crushing All - in - One Machine has a wide crushing range and can be used for crushing fibrous scale - like materials such as thatch, corn stalks, and sorghum stalks. It is widely applied in the crushing and processing of crop straws, straw pellet fuels, biomass power generation, and many other fields. It is an ideal processing equipment for charcoal factories, straw coal factories, biomass pellet processing factories, etc.

The Rotary Cutting and Crushing Machine is a high - performance equipment, highly suitable for crushing agricultural and biomass materials. It is mainly composed of a base, a gear transmission device, and a rotating box. It can efficiently crush various crop straws, such as corn straws, wheat straws, rice straws, alfalfa grass, Pennisetum alopecuroides, logs, etc. It can also crush wooden boards or strips with dimensions less than 800x100x10mm (thickness), as well as board skins. For bundled materials, there is no need to untie the bundles; they can be directly put into the rotating drum for crushing.

Advantage Introduction

Safety Usage Skills of Straw Rotary Cutting Machine

(1) The straw rotary cutting machine should be fixed on the ground, and cement can be used for fixation. If the working location needs to be changed frequently, the crusher and the motor should be installed on a machine base made of angle steel.

(2) Before the straw rotary cutting machine starts working, the staff should carefully check the materials to prevent hard objects such as metals and stones from entering the crushing chamber and causing accidents.

(3) Before starting the straw rotary cutting machine, first check whether the operation is flexible and normal, whether there are any collision phenomena inside the machine shell, whether the rotation direction of the rotor is correct, and whether the lubrication of the motor and the crusher is good.

(4) After starting the straw rotary cutting machine, it should be idled for 2 - 3 minutes. Only when there are no abnormal phenomena can the feeding work begin.

(5) Do not frequently change the pulley of the straw rotary cutting machine to prevent the speed from being too high or too low.

(6) When feeding the straw rotary cutting machine, if abnormal noises, excessively high temperatures of the bearing and the machine body, or material spraying out are found, the machine should be stopped immediately for inspection and troubleshooting.

(7) Before stopping the straw rotary cutting machine, stop feeding first. After all the materials inside the machine are discharged, cut off the power supply and stop the machine.

(8) After the straw rotary cutting machine has been in operation for 300 hours, the bearing must be cleaned and the lubricating oil must be replaced.