All - in - one Crushing and Powdering Machine

Robust Feeding Chain Plate: The one - piece stamped feeding chain plate of the integrated crushing and pulverizing machine enhances its rigidity, making it durable for harsh working conditions.

Intelligent Feeding & Hydraulic System:

Equipped with a current detection system, it automatically pauses feeding when overloaded and resumes after processing, minimizing jams.

The internal hydraulic motor feeding system prevents leakage, resists blockages, offers a long service life, quick start - up, and high torque. It can self - adjust during blockages, reversing and then re - feeding.

Efficient Cutting & Metal Removal:

Integrated Crushing and Powdering Machine:

Our Integrated Crushing and Powdering Machine is a high - tech solution, designed to meet various industrial needs.

Diverse Application Scenarios

2.Agricultural Waste Treatment:

Farmers and agricultural processing plants often face the problem of dealing with agricultural waste, such as crop stalks and husks. Our integrated machine can effectively process these wastes. The crushed and powdered materials can be used for composting, soil improvement, or as bedding materials for livestock, thus turning waste into valuable resources and improving the sustainability of agricultural production.

3.Municipal Solid Waste Recycling

Municipal solid waste is composed of diverse materials, many of which are recyclable. Our machine is specifically designed to handle the organic and recyclable parts within municipal waste. For instance, it can effectively break down waste paper, cardboard, and certain plastic - wood composite materials. By doing so, it enables the separation of various substances for subsequent recycling, thereby decreasing the amount of waste that ends up in landfills and facilitating the growth of a circular economy.

4. Quarry and Aggregate Production

In the quarry and aggregate production sectors, our machine proves highly valuable for processing stones and rocks. It can efficiently crush large - sized stones into smaller aggregates with different particle sizes, which are indispensable for construction activities like road construction and concrete manufacturing. Thanks to the machine's high - efficiency operation and precise particle - size control capabilities, the quality of the produced aggregates is consistently guaranteed.

Advanced Operation Features:

Model

POWER(KW)

Output(T/H)

TR-C72140

200+5.5+5.5 +7.5+1.5+2.2

3-5

TR-C72140

250+5.5+5.5 +7.5+1.5+2.2

4-6

TR-C90150

315+18.5+0.13

6-10

TR-C90150

200*2+18.5+ 0.13

7-12

TR-C90150

250*2+18.5+ 0.13

8-14

TR-C90150

315*2+18.5+ 0.13

10-16

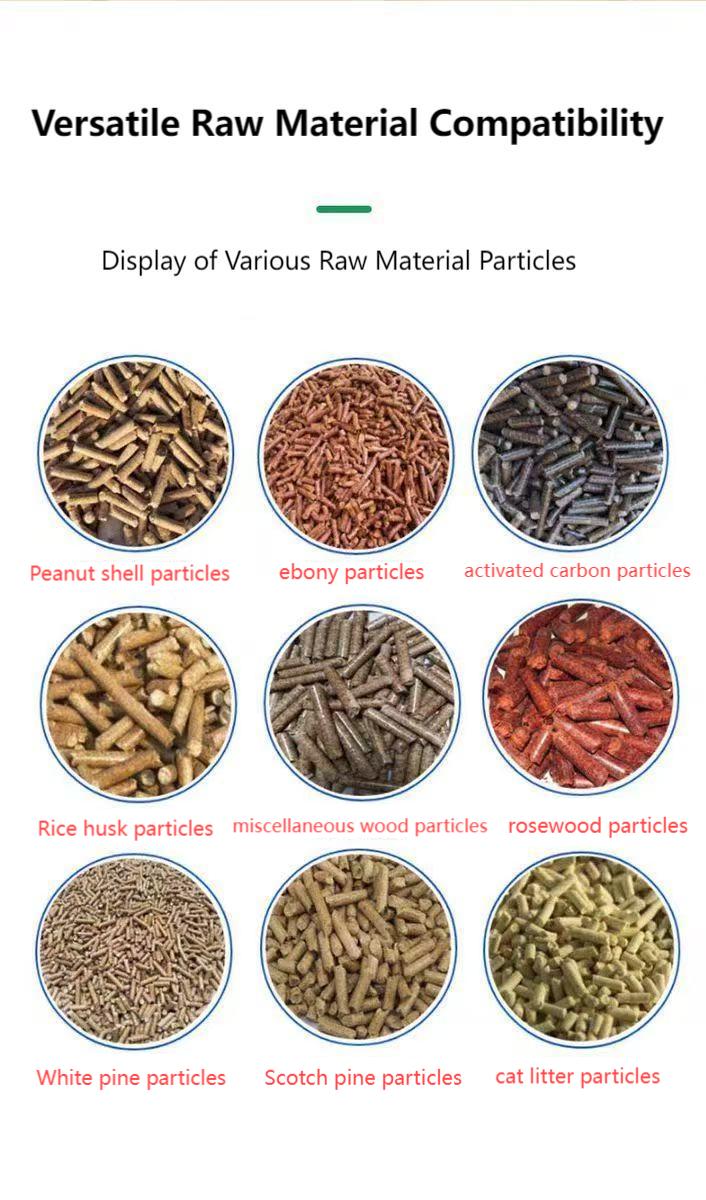

various materials with ease.

Flexible & Durable:The machine can be frequently started and moves smoothly forward and backward.

With a long lifespan, sensitive start - up, and high torque, it adapts well to different working conditions, reducing breakdowns.

Powerful & Replaceable Knives:Equipped with heavy - hammer - type, super - wear - resistant knives, it's easy to replace them.

This design improves crushing efficiency and material processing, handling

Transparent Pricing:

We know cost matters. When investing in our machine, expect clear pricing. Factors like capacity, material quality, extra features,

and brand reputation determine the price. Our simple structure helps you compare and make a smart buying decision.

Advanced Tech & Robust Build:

The machine uses advanced technology for smooth operation. Its innovative crushing mechanisms handle diverse materials easily. Built with quality materials, it's durable in harsh conditions, reducing maintenance and extending service life.