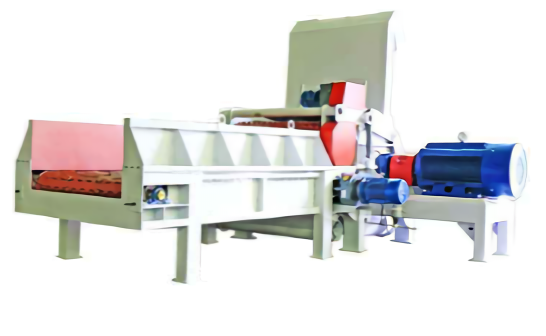

Best Pellet Integrated Crushing and Powdering Machine

Advantages of the feeding chain plate design

The single - step stamped feeding chain plate has enhanced rigidity, is more robust and durable, and can better withstand harsh working conditions.

Advantages of the current detection system and feeding control

The current detection system automatically pauses and resumes feeding based on processing ability, reducing material blockages and machine malfunctions.

Advantages of the hydraulic motor in the feeding system

The internal hydraulic motor in the feeding system prevents leakage, resists blockages, has a long service life, quick start - up, and high torque. It can handle blockages and resume feeding after a delay.

Advantages of the heavy - hammer - type knives

Heavy - hammer - type blades made of wear - resistant materials are easily replaceable, improving crushing efficiency and fineness.

Advantages of the two - stage metal removal process

The two - stage metal removal process expels heavier metals and efficiently eliminates non - magnetic metals, ensuring operational safety.

Integrated Crushing and Powdering Machine

Our Integrated Crushing and Powdering Machine represents a cutting - edge technological innovation, meticulously engineered to fulfill a wide spectrum of industrial requirements.

Versatile Material Processing

The integrated crushing and pulverizing machine excels at handling metal - laden materials. It efficiently processes construction templates, wooden pallets, demolition wood, second - hand wooden furniture, along with waste from furniture and flooring factories. Customers can directly transform a wide range of trees, timbers, construction formworks, and wooden pallets into raw materials ready for fuel pellet pressing in a single operation. Unlike the old - fashioned setup with two distinct machines for sequential crushing and pulverizing, this new model simplifies the workflow by removing an intermediate step, thereby slashing operational costs.

Diverse Application Scenarios:

Biomass Energy Industry

Processes straw, wood chips, etc. for power generation and biofuel production, promoting renewables and reducing fossil fuel use.

Agricultural Waste Treatment

Handles crop stalks and husks, turning waste into compost, soil improvers, or livestock bedding for sustainable farming.

Municipal Solid Waste Recycling

Processes organic and recyclable waste like paper and composites, aiding material separation, reducing landfill waste, and advancing the circular economy.

Quarry and Aggregate Production

Crushes large stones into various - sized aggregates for construction, ensuring quality with high - efficiency and precise size control.

Advanced Operation Features:

Flexible & Durable:The machine can be frequently started and moves smoothly forward and backward. With a long lifespan, sensitive start - up, and high torque, it adapts well to different working conditions, reducing breakdowns.Powerful & Replaceable Knives:Equipped with heavy - hammer - type, super - wear - resistant knives, it's easy to replace them. This design improves crushing efficiency and material processing, handling various materials with ease.

Model | POWER(KW) | Output(T/H) |

TR-C72140 | 200+5.5+5.5 +7.5+1.5+2.2 | 3-5 |

TR-C72140 | 250+5.5+5.5 +7.5+1.5+2.2 | 4-6 |

TR-C90150 | 315+18.5+0.13 | 6-10 |

TR-C90150 | 200*2+18.5+ 0.13 | 7-12 |

TR-C90150 | 250*2+18.5+ 0.13 | 8-14 |

TR-C90150 | 315*2+18.5+ 0.13 | 10-16 |

Transparent Pricing

We recognize that cost is a pivotal factor. When you invest in our machine, rest assured that the pricing will be crystal clear. The price is influenced by elements such as capacity, material grade, additional functions, and brand standing. Thanks to its uncomplicated structure, you can effortlessly make comparisons and arrive at an informed purchasing decision.

Advanced Tech & Sturdy Construction

Our machine incorporates state - of - the - art technology, ensuring seamless operation. Its cutting - edge crushing mechanisms can effortlessly handle a wide variety of materials. Constructed from top - quality materials, it can withstand tough environments, minimizing maintenance requirements and prolonging its service life.

Comprehensive After - sales Service

Dependable Support

Alongside its excellent performance, we offer extensive after - sales assistance.

Complimentary Technical Support

We offer free technical support to all our customers. Whether you face issues during machine setup, startup, operation, or regular maintenance, our professional technical team is available around the clock. We’ll do everything in our power to address your concerns and offer practical solutions.

One - year Full - machine Warranty

Our integrated crushing and powdering machine comes with a one - year warranty. During this period, if any malfunctions arise due to quality defects, we’ll provide free repair services and replace any defective components. It's important to note that this warranty does not cover auxiliary equipment, damage caused by human error, or the replacement of wear - and - tear parts.

Lifelong Maintenance (Excluding Auxiliary Equipment, Human - induced Damage, and Wear - part Replacement)

We provide maintenance services for the entire lifespan of the product. Even after the warranty expires, our technicians will still offer professional repair services. However, for issues with auxiliary equipment, damage resulting from human actions, and the replacement of parts subject to normal wear, customers will be responsible for the associated costs. We are committed to keeping your machine in optimal working condition with affordable prices and efficient service.

Company Profile

Series of products are: wood pellet machine, straw pellet machine, biomass pellet machine, sludge briquetting machine, airflow, drum series drying equipment; cutting, crushing series of equipment, and other ancillary cooling equipment, screening equipment, packaging equipment, conveying equipment, such as a full set of biomass pellet production line equipment. The company's technical personnel according to the different needs of customers and customer plant space for customized configuration and design.