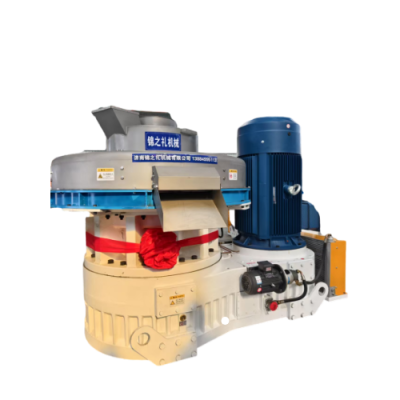

Robust Bagasse Pellet Machine

1.High automation

This machine features a high level of automation, eliminating the need for continuous, dedicated supervision. During its operation, you are able to monitor the temperature of crucial components and the equipment's current through the control panel, tablet, or even a mobile application.

2.Flexible lubrication mode

There is an easy transition available between independent lubrication and non - independent lubrication.

3.Enhanced drive system

The drive of the reducer has been significantly improved. The gearbox is equipped with a large, self - developed gear and a three - level drive system. By increasing the module, the gears have been made more robust.

4.Excellent die performance

The die is crafted from stainless steel, demonstrating outstanding wear resistance and a high production capacity. The die of our biomass pellet machine is constructed from integrally carburized stainless steel. It is extremely wear - resistant, highly stable, and the discharge area has been enlarged. As a result, it enhances the production capacity and reduces costs.

Applicable Materials

The Robust Type 850 Bagasse Pellet Machine can compress forestry and agricultural raw materials such as trees, tree bark, branches, wood chips, and crop straws, as well as solid waste like engineering construction formwork, fruit shell residues, and industrial sludge into biomass pellet fuel. This not only helps with energy conservation and emission reduction but also contributes to the construction of a sustainable ecological environment.

Product Features

1.Elevated Kinetic Energy Transformation

By directly linking the motor to the reducer's gearbox, the direct - drive setup remarkably improves the kinetic energy conversion efficiency. This leads to a considerable boost in the overall production productivity.

2.Sturdy Load - Handling and Long - lasting Press Wheel

Utilizing a three - stage gear reducer greatly strengthens the machine's load - bearing ability. Significantly, the press wheel now uses a super - abrasion - resistant alloy welding technique instead of the former surface carburization treatment. This advancement not only prolongs the press wheel's service life but also provides better safeguarding for the mold, enabling stable and sustained operation.

3.Effective Lubrication and Cooling Mechanism

The gearbox is furnished with an integrated lubrication and cooling system. This system can cool the lubricating oil efficiently while the machine remains in operation. Consequently, it ensures seamless and uninterrupted running, reducing possible operational interruptions.

4.Dependable Toggle Assembly and Premium Molds

The novel toggle system with external rotating parts efficiently overcomes the problem of high - temperature steam corrosion, thus ensuring enhanced longevity. The molds, made from wear - resistant stainless steel and treated via vacuum furnace quenching, have consistent hardness and excellent wear - resistance. They are highly resilient to cracking, ensuring reliable and steady performance at all times.

Product Attributes

Model No.:GE850 | Brand:GOLDEN EQUATION |

Energy Saving:Energy Saving | Automatic Grade:Semiautomatic |

control mode:Manual control | Warranty:1Year |

Customized:Customized | Spare Parts:Roller Shell+Mould |

Moisture:13%-15% | Application:Press Wood Sawdust Into Pellets |

Motor:Chinese Famous Brand | Pellet Diameter:6-12mm Customizable |

After-sale Service:Engineers are available and they are eligible to apply for visas. | |

Company Profile

Our company places great emphasis on building enduring customer partnerships. Through top-notch products and meticulous attention to detail, we've accompanied and witnessed the development of numerous customers. We're convinced that quality paves the way for market presence, and service is the cornerstone of a good reputation. Quality and efficiency are the bedrock for an enterprise to thrive, while service and reputation are the driving forces behind its advancement.