Cooler Counter for Small Business

Smooth Operation

Automation Feature

Efficient Cooling

Components of the Counterflow Cooler

Product features

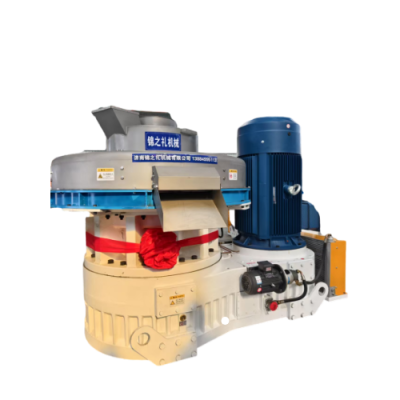

The machine has a unique cooling mechanism, the cooling wind and particles reverse movement, so that the material is gradually cooled from top to bottom, avoiding the general vertical cooler due to the sudden cooling caused by the particle surface cracking, the heart of the water and heat in the cooling time is difficult to disseminate as well as fragile and other shortcomings.

1. Counterflow cooler adopts modular structure type installation, which is easy to transport and install.

2. Counterflow cooler adopts unique vibration type mechanism to discharge materials smoothly.

3. Countercurrent cooler is set up with material leveler, which can monitor the position of materials in the silo in real time.

4.Countercurrent cooler uses countercurrent cooling principle to make the particles cool evenly and fully.

Parameter

Model | Output | Power | Cooling volume | Cooling time | Cooling material temperature |

SKLN-1.5 | 1-2 | 1.1+0.18+5.5 | 1.5 | ≥6-10 | ≤3-5 |

SKLN-2.5 | 2-3 | 2.2+0.18+11 | 2.5 | ≥6-10 | ≤3-5 |

SKLN-4 | 4-6 | 2.2+0.25+22 | 4 | ≥6-10 | ≤3-5 |

SKLN-6 | 7-10 | 3+0.25*2+37 | 6 | ≥6-10 | ≤3-5 |

SKLN-8 | 10-15 | 3+0.25*2+55 | 8 | ≥6-10 | ≤3-5 |

SKLN-10 | 15-20 | 3+0.25*2+75 | 10 | ≥6-10 | ≤3-5 |

Company Profile

Our series of products include: wood chip pellet machines, straw pellet machines, biomass pellet machines, sludge briquetting machines, air flow and drum series drying equipment; cutting and crushing series equipment, as well as other supporting cooling equipment, screening equipment, packaging equipment, conveying equipment, and a full set of biomass pellet production line equipment. The company's technicians will customize the configuration and design according to the different needs of customers and the actual space of the customers' factory buildings.