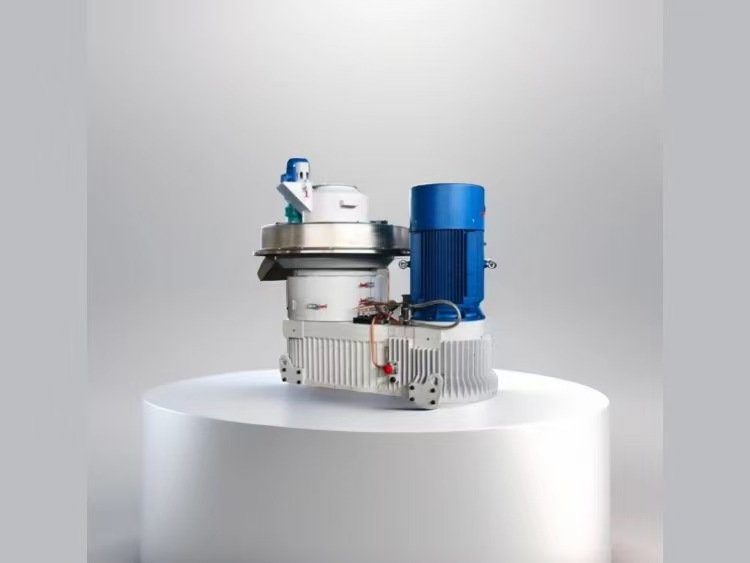

1.5-5 Ton Per Hour Type 560 Bagasse Pellet Machine

Type 560 Bagasse Pellet Machine

Product Attributes

Model No.:GE560 | Brand: GOLDEN EQUATION |

Energy Saving:Energy Saving | Automatic Grade:Semiautomatic |

control mode:Manual control | Warranty:1Year |

Customized:Customized | Spare Parts:Roller Shell + Mould |

Moisture:13%-15% | Application: Press Wood Sawdust Into Pellets |

Motor:Chinese Famous Brand | Pellet Diameter:6-12mm Customizable |

After-sale Service:Engineers are available and they are eligible to apply for visas. | |

Product Features

Parameter

Category | Model | Power(KW) | Pellet size(mm) | Output(t/h) | Overall Dimension(mm) | Machine Weight(T) |

Vertical ring mould | JL560 | 132 | 6-12 | 1.5-2 | 2200*1280*1640 | 5T-5.5T |

JL560 | 160 | 6-12 | 1.5-2 | 2200*1280*1640 | 5T-5.5T |

The discharging output varies due to different feeding at the front - end. For details, please leave a message for consultation.

Company Profile

Our company is committed to forging lasting customer partnerships. By providing top - tier products and demonstrating meticulous dedication, we have accompanied and witnessed the development of numerous clients. We are firmly convinced that quality is the prerequisite for market access, while service is the cornerstone for building a good reputation. For our company, maintaining high - quality standards and operational efficiency is essential for establishing a strong market position, and delivering excellent service and upholding a good reputation are crucial for driving continuous growth.