Wood Pellet Machine

Supply Ability & Additional Information

Packaging: shipping by container

Productivity: 2.5-3.5 T/H

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 50 set per month

Port: Qingdao, Shanghai, etc.

Payment Type: L/C,T/T,D/P,Western Union

Incoterms: FOB,CFR,CIF,EXW

Packaging & Delivery

Selling Units: Set/Sets

Package Type: shipping by container

Container types: 40HQ/40FR (flat rack container), with support for oversized cargo transportation.

Compliance Documents:

Applicable Materials for Type 850 Bagasse Pellet Machine

The Type 850 Bagasse Pellet Machine is great at processing sawdust. As a common woodworking by - product, sawdust can be efficiently made into high - quality biomass pellets by this machine.

Its advanced design and strong compression let it handle large amounts of sawdust, turning it into dense, uniform pellets used in heating, power generation, and industrial boilers.

Besides sawdust, it can process other fibrous materials like bagasse from sugarcane and various agri - forestry by - products. This wide applicability makes it a valuable tool for industries turning waste into energy, helping with conservation and a greener environment.

1. Product Overview

The 850 Type Wood Pellet Machine is a high - performance biomass granulation equipment designed to transform a variety of biomass materials into high - density pellets. With a production capacity ranging from 3 to 5 tons per hour (T/H), it is suitable for both small - scale enterprises and large - scale industrial production.

2.Product Features

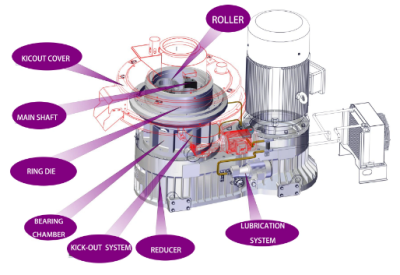

Efficient Kinetic Energy Transfer:The motor directly connects to the reducer's gearbox. This setup boosts kinetic energy conversion, significantly enhancing production efficiency.

Sturdy Press Wheel with Longevity:A three - stage gear reducer increases load - bearing capacity. The press wheel, now using super - wear - resistant alloy welding instead of surface carburization, lasts longer and better protects the mold for stable operation.

Smooth Lubrication and Cooling:The gearbox has a built - in lubrication and cooling system. It cools the oil during operation, ensuring continuous and trouble - free running.

Durable Toggle and High - Quality Molds:The new external rotary toggle system resists high - temperature steam erosion. Molds made of wear - resistant stainless steel, vacuum - furnace quenched, are hard, wear - resistant, and less likely to break, ensuring reliable performance.

Product Attributes

Model No.:GE850 | Brand:GOLDEN EQUATION |

Energy Saving:Energy Saving | Automatic Grade:Semiautomatic |

control mode:Manual control | Warranty:1Year |

Customized:Customized | Spare Parts:Roller Shell+Mould |

Moisture:13%-15% | Application:Press Wood Sawdust Into Pellets |

Motor:Chinese Famous Brand | Pellet Diameter:6-12mm Customizable |

After-sale Service:Engineers are available and they are eligible to apply for visas. | |

3. Working Principle

The working process of the 850 Type Wood Pellet Machine is as follows:

Feeding

The prepared biomass materials are fed into the machine through a feeding system. The feeding system is designed to ensure a continuous and stable feed rate, which is crucial for the smooth operation of the granulation process.

Compression and Granulation

Inside the machine, the materials are first pre - pressed and then forced through the holes of the ring die by the rotating rollers. The high pressure during this process compresses the biomass materials into dense pellets. The diameter of the pellets can be adjusted according to individual needs, usually available in sizes such as 6mm, 8mm, and 10mm.

Discharging

The formed pellets are discharged from the machine and then can be further processed, such as cooling, screening, and packaging.

Die: stainless steel,with high wear resistance and high capacity. Die of biomass pellet machine adopt integral carburizing stainless steel, high wear resistance, good stability, discharge area increase, enhance the capacity and reduce cost.

Company Profile

The company focuses on cultivating long-term customer relationships, with high quality products and scrupulous dedication to accompany and witness the growth of many of our customers. We firmly believe that there is a market only with quality and a reputation only with service. Quality and efficiency are the fundamentals to win a foothold in the enterprise, and service and reputation are the keys to win the progress of the enterprise.