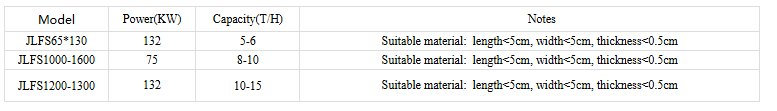

The introduction of Sawdust Machine

A full pulverizer set consists of the pulverizer host, fan, saxophone, shut - off fan, dust bag and other elements. Prior to assembly, the main components of the pulverizer, especially the rotor, are dynamically balanced to guarantee stable operation of the machine. Moreover, the motor base assembly platform and the rotor spindle bearing seat assembly platform are machined simultaneously on a large - scale CNC machine tool in one operation. Such precision enables the machine to run smoothly and with the highest accuracy.

High - efficiency crushers find extensive application in the biomass energy and feed processing sectors. This apparatus is capable of crushing a wide range of raw materials, such as: Wood: pine, poplar, fir, bamboo, branches, bark, wood chips, shavings, etc. Straw: corn straw, wheat straw, rice straw, rice husks, peanut shells, cotton stalks, etc.

![Sawdust Machine.jpg Sawdust Machine.jpg]()

![Sawdust Machine.jpg Sawdust Machine.jpg]()

![Sawdust Machine.png Sawdust Machine.png]()

The Main Wearing and Replacing Parts of the Hammer Mill Are as Follows:

1.Hammer Heads

Function: They are the key working components of the hammer mill that directly strike and crush the materials. They crush the materials by impacting them through high-speed rotation.

Reasons for Wear: Continuous impacts, cutting, and crushing of the materials cause wear due to long-term repeated actions. High hardness of the materials, large and uneven feed particle size will intensify the wear. When the equipment runs continuously for a long time and the hammers are constantly under stress, the wear will also be accelerated.

Materials and Characteristics: Commonly used materials include high manganese steel, which has a low cost but limited wear resistance, and it is difficult to repair when severely worn. High chromium cast iron has high hardness and good wear resistance, but relatively poor toughness. Alloy steel has better comprehensive performance and is suitable for crushing materials with high hardness.

Replacement Judgment: When the surface of the hammer is severely worn, deformed, or has obvious cracks, or when it leads to a deterioration of the crushing effect (such as uneven particle size of the output materials, decreased output), reduced production capacity, and frequent blockages of the equipment, replacement should be considered.

![hammer head.png hammer head.png]()

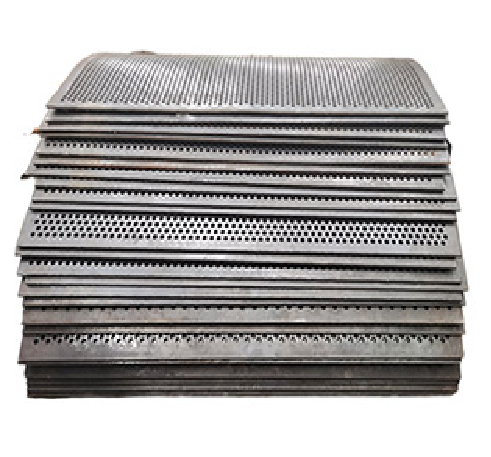

2.Screen Mesh

Function: It screens the crushed materials, controls the particle size of the discharged materials, and ensures that the product particle size meets the requirements.

Reasons for Wear: It is subject to the friction and impact of the crushed materials passing through. Hard objects mixed in the materials will cause local concentrated wear on the screen mesh. Long-term use of the screen mesh will lead to a decrease in its own strength due to fatigue, which will also accelerate the wear.

Materials and Characteristics: Common materials include stainless steel, which has strong corrosion resistance and is suitable for screening wet or corrosive materials. Manganese steel has high strength and good wear resistance and is often used for handling materials with relatively high hardness.

Replacement Judgment: When the screen mesh has large-area damage, the mesh size becomes larger beyond the allowable range, or the screening efficiency is significantly reduced (such as a large number of materials that do not meet the particle size requirements passing through), it needs to be replaced.

![Screen Mesh.png Screen Mesh.png]()

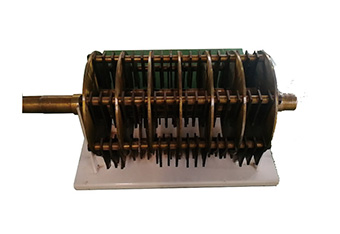

3.Rotor

Function: As a component that supports the hammers and drives them to rotate at high speed, it is a key moving component for the hammer mill to achieve the crushing function.

Reasons for Wear: By driving the hammers to rotate at high speed for a long time, it itself bears a large centrifugal force and impact force, and parts such as the journal are prone to wear. When materials enter the gap between the rotor and the machine body, abrasive wear will occur. Poor lubrication, insufficient installation accuracy, etc. will intensify the wear of the rotor.

Materials and Characteristics: It is generally made of high-quality steel, such as medium carbon steel or alloy steel, and its strength and wear resistance are improved through heat treatments such as quenching and tempering.

Replacement Judgment: When the wear of the rotor journal exceeds the tolerance range, it affects the matching accuracy with the bearing and causes the vibration of the equipment to intensify. When the rotor has severe deformation or cracks, which affects the operation stability and safety, or when the balance accuracy is seriously lost and still cannot meet the requirements after dynamic balance correction, replacement should be considered.

![Rotor.png Rotor.png]()

Company Profile

Our firm holds the belief that quality and efficiency are the cornerstones for an enterprise's establishment, and service and quality are the catalysts for an enterprise's progress. The product series features wood chip pellet machines, straw pellet machines, biomass pellet machines, sludge briquetting machines, air flow and drum series drying equipment. Moreover, we have cutting and crushing series equipment, and a full set of biomass pellet production line equipment, like other auxiliary cooling, screening, packaging, and conveying equipment. The company's technical personnel will customize and plan the equipment based on the different demands of customers and the actual space of their factory buildings.

![company.jpg company.jpg]()

![company.jpg company.jpg]()