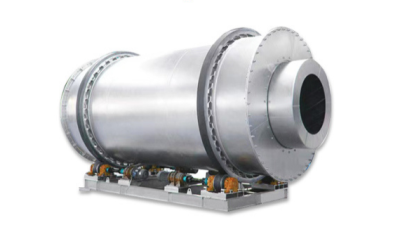

Wood Pellet Machine

Automation and Convenience:With a high degree of automation and stable operation, it requires no dedicated personnel on standby. This significantly reduces labor costs, providing a more worry - free user experience.

Efficient Production:The enlarged discharging area effectively boosts production capacity, meeting the demands of large - scale production and facilitating capacity upgrades.

Energy - Saving and Durable Design:The press roller adopts a non - locknut structure, reducing fuel consumption and extending the service life of bearings, achieving a win - win situation in energy conservation and durability.

Reliable Transmission System:Driven by a heavy - duty gearbox, the gear strength is enhanced 5 to 10 times, resulting in a low failure rate. It ensures stable operation of the equipment and minimizes maintenance concerns.

Economical Lubrication Method:Circulating gear oil lubrication reduces the cost of grease consumption and provides excellent protection for bearings, saving maintenance expenses.

Wide Applicability:As a specialized biomass pellet machine, it is suitable for various raw materials such as sawdust, agricultural straw, rice husk, sunflower shell, palm fiber, bamboo, etc., offering a rich range of application scenarios.

Product Features of Wood Pellet Machinet Machine

High - efficiency production: The direct connection between the motor and the reducer's gearbox enhances the kinetic energy conversion rate and boosts production efficiency.

Durable design: The three - stage gear reducer increases the load capacity. The press wheel uses a super wear - resistant alloy welding process instead of surface carburization, which extends its service life and better protects the mold.

Smooth operation: The gearbox is equipped with a built - in lubrication and cooling system, enabling effective cooling of the lubricating oil without stopping the machine.

Robust and reliable: The new toggle system with external rotary components solves the problem of high - temperature steam erosion, ensuring greater durability. The molds are made of wear - resistant stainless steel and undergo vacuum furnace quenching, resulting in uniform hardness, exceptional wear resistance, and no breakage.

Product Attributes

Model No.:GE560 | Brand:Golden Equation |

Energy Saving:Energy Saving | Automatic Grade:Semiautomatic |

control mode:Manual control | Warranty:1Year |

Customized:Customized | Spare Parts:Roller Shell+Mould |

Moisture:13%-15% | Application:Press Wood Sawdust Into Pellets |

Motor:Chinese Famous Brand | Pellet Diameter:6-12mm Customizable |

After-sale Service:Engineers are available and they are eligible to apply for visas. | |

Additional Information

| Productivity | 1.5-2t/h |

| Transportation | Ocean,Air |

| Place of Origin | Jinan, Shandong |

| Supply Ability | 500 setS per year |

| HS Code | 84793000 |

| Port | Qingdao,China |

| Payment Type | L/C,T/T |

| Incoterm | FOB,CFR,CIF,EXW |

Purpose

Our Wood Pellet Machinet can compress all kinds of biomass raw materials, like grass, sawdust, rice husks, peanut shells, and straw, into solid pellets. These finished pellets are great for combustion.

Features

This is an energy - saving device. The pellet machine has a high degree of automation and saves labor.

Components

The whole pellet machine includes crushers or hammer mills, dryers, pellet machines, finishing machines, pellet packaging machines and other auxiliary equipment (conveyors, electrical control cabinets, etc.)

Service Advantages

We can design a suitable pellet production line with pellet machines for you according to your raw material conditions and required production capacity.

Company Profile

Series of products are: wood pellet machine, straw pellet machine, biomass pellet machine, sludge briquetting machine, airflow, drum series drying equipment; cutting, crushing series of equipment, and other ancillary cooling equipment, screening equipment, packaging equipment, conveying equipment, such as a full set of biomass pellet production line equipment. The company's technical personnel according to the different needs of customers and customer plant space for customized configuration and design.