The Three - cylinder dryer is mainly used for drying wet materials in the form of powder, granules, small lumps, etc.and is widely applied in industries such as energy, fertilizers, chemicals, and pharmaceuticals.

The working process of a drum dryer is as follows:

Feeding: Wet materials are fed into the drum dryer through a feeding device. The feeding speed and quantity can be adjusted according to the production requirements to ensure a stable and continuous supply of materials.

Heating: Inside the drum, there are heating elements or hot air channels. Hot air or other heat sources are introduced to raise the temperature inside the drum. The temperature can be controlled precisely to meet the drying requirements of different materials.

Drying: As the drum rotates, the wet materials are constantly lifted and tumbled by the blades or baffles inside the drum. This allows the materials to be evenly exposed to the hot air, facilitating heat transfer and mass transfer. The moisture in the materials evaporates and is carried away by the flowing hot air.

Exhausting: The moist air containing evaporated water is discharged from the drum dryer through an exhaust system. The exhaust system may include filters and other devices to remove dust and other impurities from the air to meet environmental protection requirements.

Discharging: After the materials are dried to the required moisture content, they are discharged from the drum dryer through a discharging device. The dried materials can then be collected and further processed or stored according to the production process.

In summary, the drum dryer uses the rotation of the drum and the action of hot air to achieve the drying of wet materials, with the advantages of high efficiency, energy saving, and uniform drying.

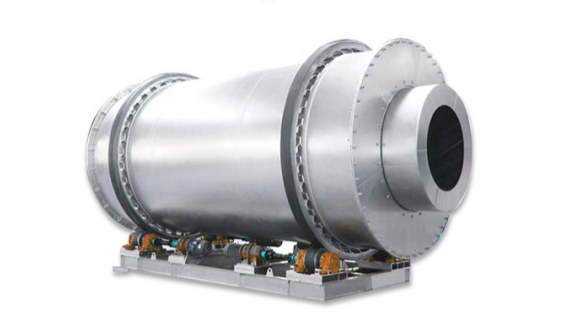

![Drum Dryer Drum Dryer]()

Product features

1.The drum dryer has a large drying capacity, capable of handling large quantities of wet materials, enhancing work efficiency.

2. The drum dryer operates smoothly, reducing the failure rate and ensuring continuous operation.

3. The drum dryer features low energy consumption, saving energy and reducing production costs.

4. The drum dryer offers convenient operation, simplifying the process and making it easy to use and maintain.

5. The drum dryer delivers high output, ensuring high production efficiency and meeting the needs of large-scale production.

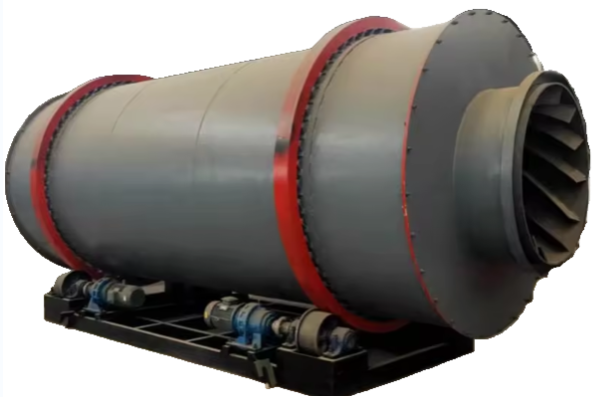

![Drum Dryer.png Drum Dryer.png]()

Company Profile

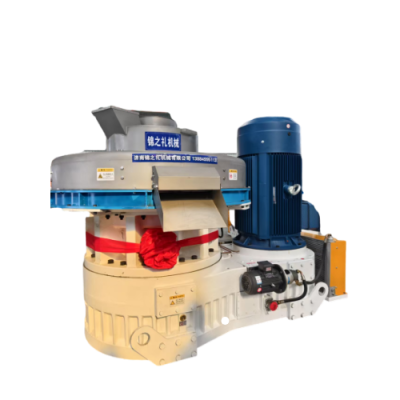

Series of products are: wood pellet machine, straw pellet machine, biomass pellet machine, sludge briquetting machine, airflow, drum series drying equipment; cutting, crushing series of equipment, and other ancillary cooling equipment, screening equipment, packaging equipment, conveying equipment, such as a full set of biomass pellet production line equipment. The company's technical personnel according to the different needs of customers and customer plant space for customized configuration and design.

![Single-Cylinder Dryer Drum Dryer.jpg Single-Cylinder Dryer Drum Dryer.jpg]()