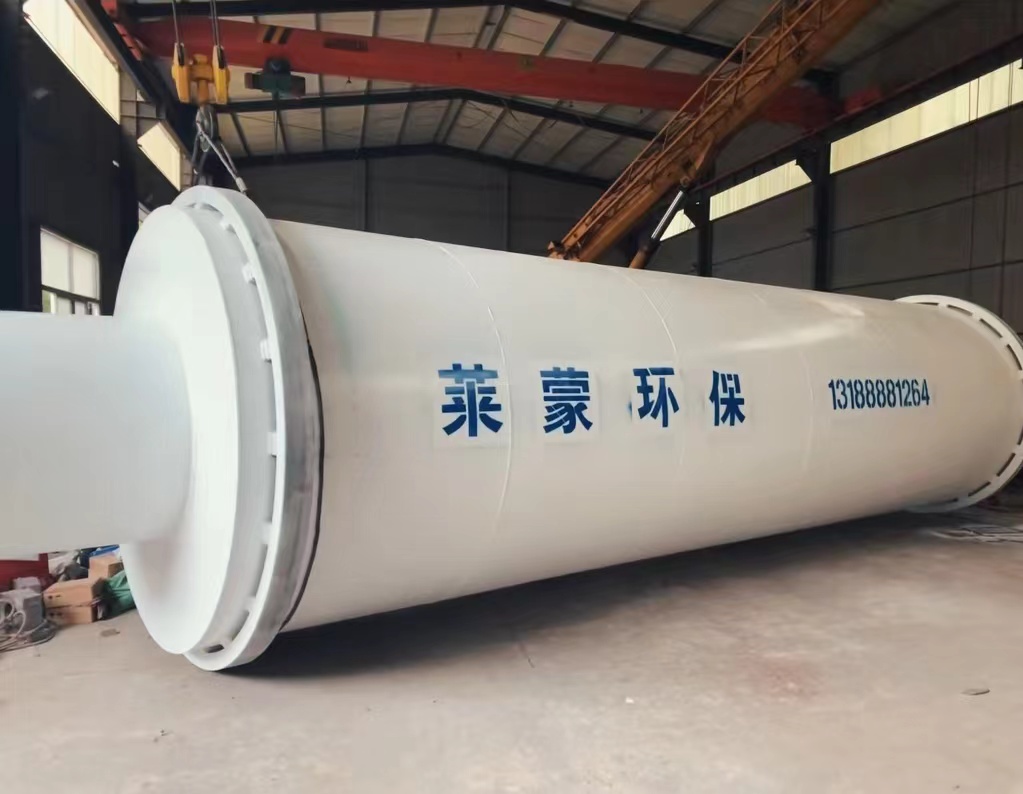

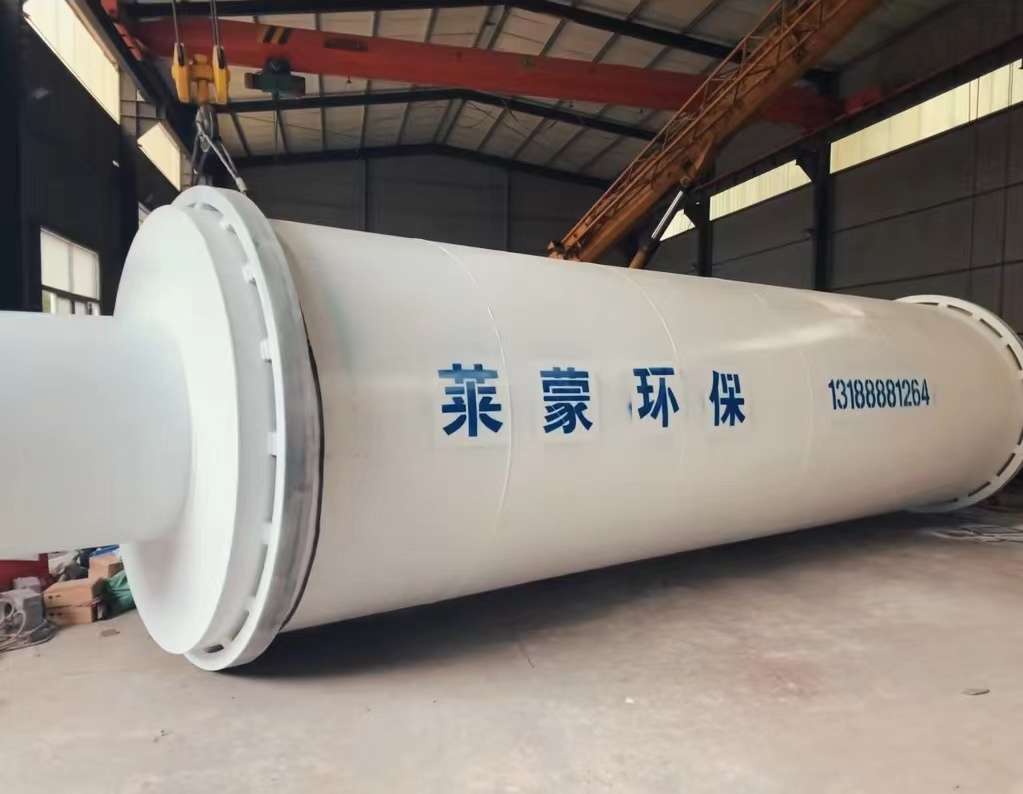

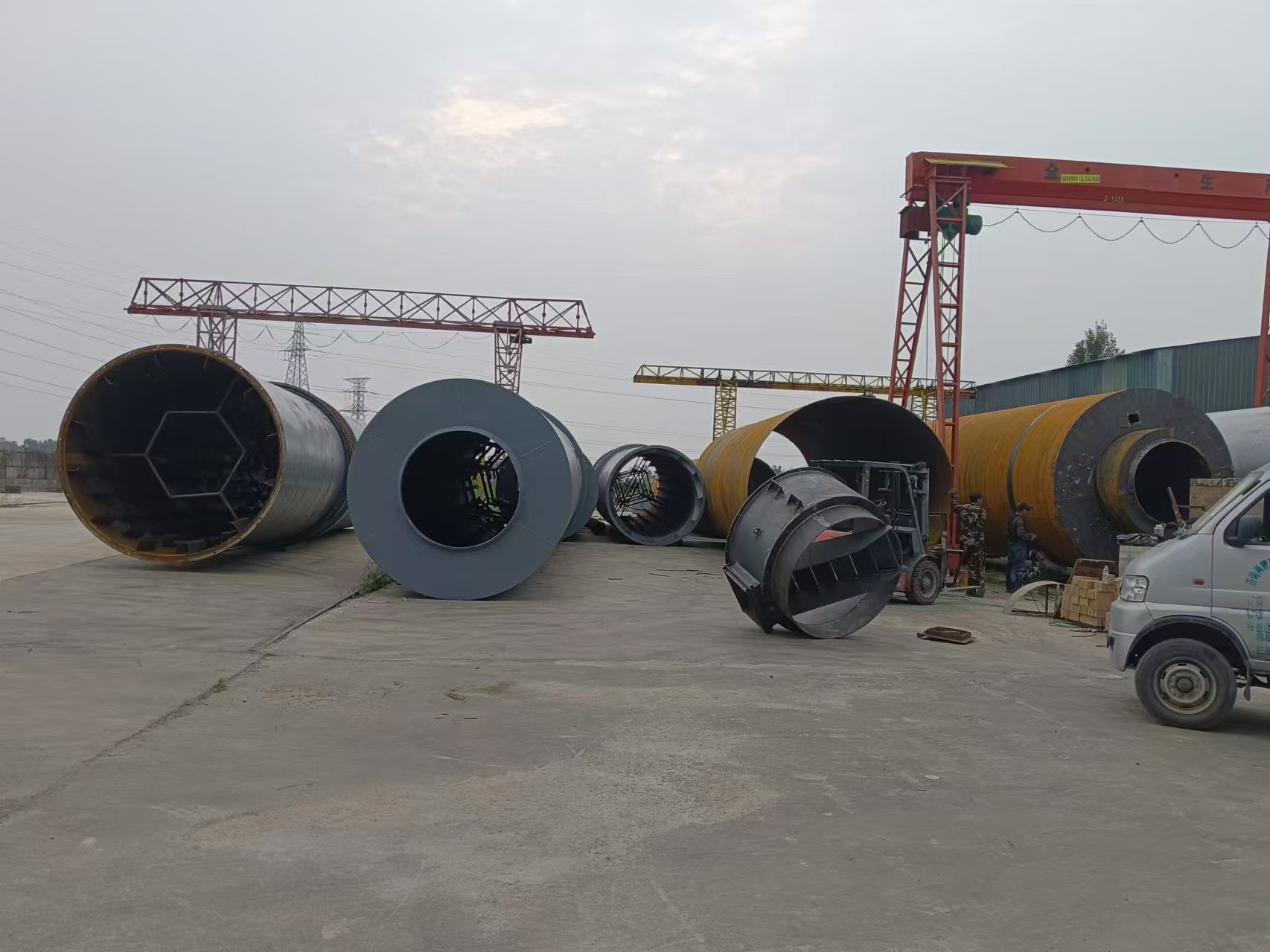

Drum Dryer

High drying capacity: It has the ability to process a large amount of wet materials, thus boosting work efficiency.

Stable operation: The equipment operates steadily, which decreases the failure rate and guarantees continuous operation.

Low energy consumption: It saves energy and cuts down production costs.

Easy operation: The operation process is simplified, making it simple to operate and maintain.

High output: With high production efficiency, it can satisfy the requirements of large - scale production.

Application and Function

Drum dryer series products are mainly used for drying powdery, granular, small lumps and other wet materials.Widely used in energy, fertiliser, chemical and pharmaceutical industries.

Usage in Biomass Granulation

In the process of biomass granulation, when the moisture content of the raw materials fails to meet the granulation requirements, drying becomes necessary.

The drum dryer is a commonly - used drying device. It has the ability to dry various materials such as wood chips, straw, and rice.

This equipment features easy operation and stable performance.

Working Principle

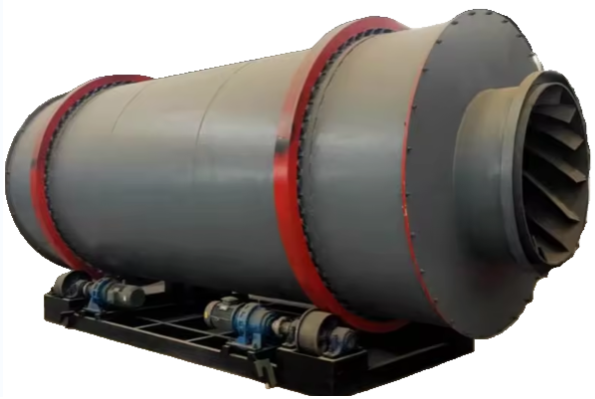

Equipment Configuration

A drum dryer alone cannot operate. Generally, it also requires a heat source (such as a hot air furnace), fans, a shakelong, and sometimes dust removal equipment.

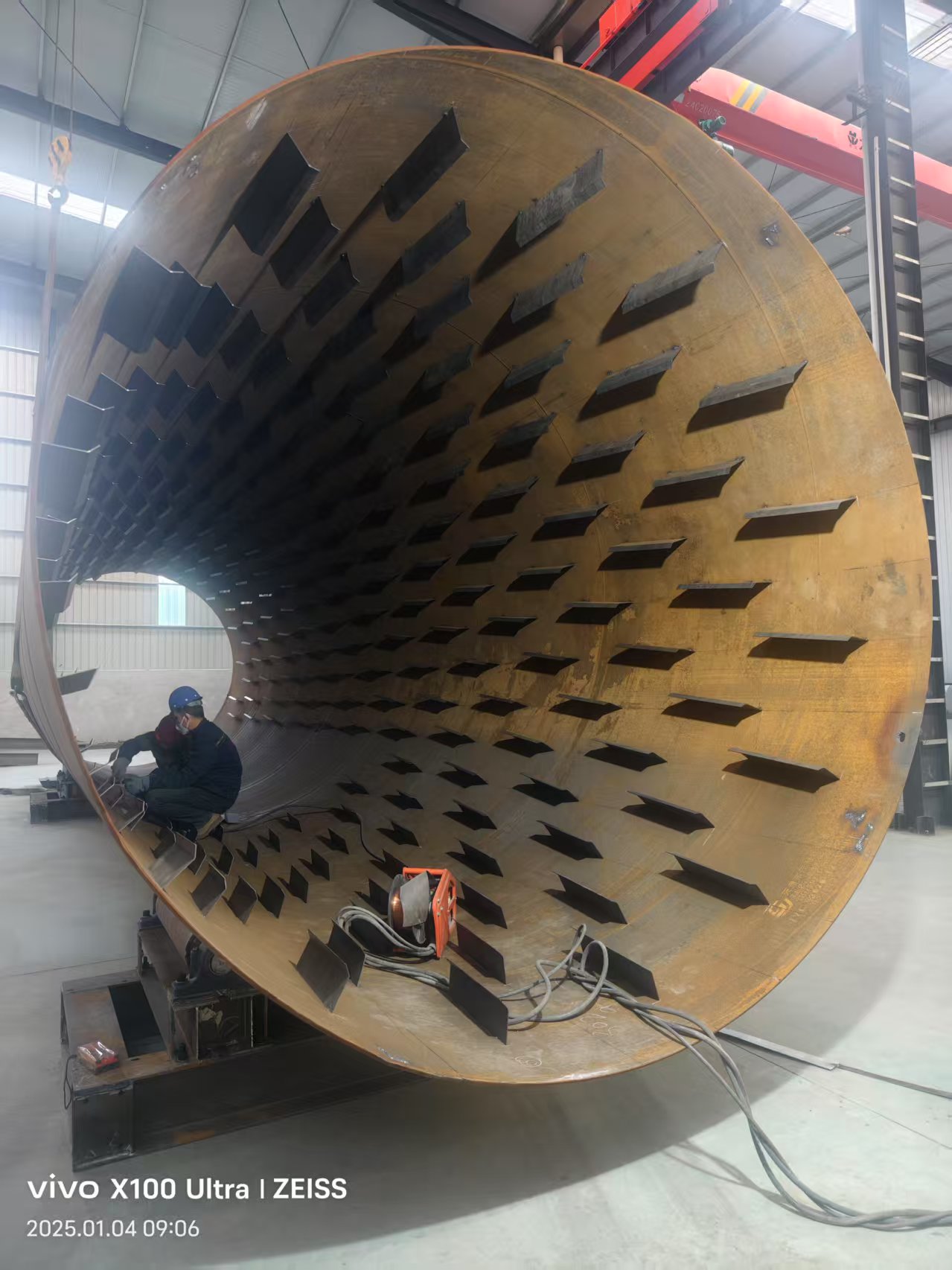

Component Composition

The drum dryer itself is composed of a cylinder, an inlet, an outlet, a toothed ring, and an aperture.

Product Characteristics

Smooth Operation

Low Energy Consumption

Convenient Operation

High Output

Parameter

Type | Model | Configuration | Evaporation(T/H) |

Single-cylinder dryer | HYHGφ1.5-12m | Main machine(7.5kw);Fan(15kw);Shaklon(φ1400);Electric control cabinet; | 0.5-0.75 |

HYHGφ1.5-15m | Main machine(11kw);Fan(18.5kw);Shaklon(φ1500);Electric control cabinet; | 0.5-0.75 | |

HYHGφ1.6-18m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 0.7-1 | |

HYHGφ1.8-15m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 1-1.3 | |

HYHGφ1.8-18m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 1-1.3 | |

HYHGφ2.0-20m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.4-2.0 | |

HYHGφ2.0-24m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.4-2.0 | |

HYHGφ2.2-24m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.7-2.5 | |

HYHGφ2.4-24m | Main machine(22kw);Fan(37kw);Shaklon(2-φ1500);Electric control cabinet; | 2.2-3 | |

HYHGφ2.8-24m | Main machine(30kw);Fan(55kw);Shaklon(4-φ1200);Electric control cabinet; | 2.5-3.6 | |

HYHGφ2.2-8-Ⅲ | Main machine(12kw);Fan(45kw);Shaklon(2-φ1200);Electric control cabinet; | 1.3-1.8 | |

HYHGφ2.4-9-Ⅲ | Main machine(12kw);Fan(45kw);Shaklon(2-φ1200);Electric control cabinet; | 1.6-2.5 | |

HYHGφ2.6-12-Ⅲ | Main machine(22kw);Fan(55kw);Shaklon(2-φ1400);Electric control cabinet; | 2.0-2.8 | |

HYHGφ2.8-12-Ⅲ | Main machine(22kw);Fan(55kw);Shaklon(2-φ1400);Electric control cabinet; | 2.1-3.0 | |

HYHGφ3.0-12-Ⅲ | Main machine(30kw);Fan(75kw);Shaklon(2-φ1500);Electric control cabinet; | 2.4-3.5 | |

HYHGφ3.2-12-Ⅲ | Main machine(30kw);Fan(90kw);Shaklon(2-φ1500);Electric control cabinet; | 3.0-5.0 |

Company Profile

Our product series include: wood pellet machines, straw pellet machines, biomass pellet machines, sludge briquetting machines, as well as airflow and drum series drying equipment; cutting and crushing series equipment, and other supplementary cooling equipment, screening equipment, packaging equipment, and conveying equipment, forming a complete set of biomass pellet production line equipment. The company's technical staff will customize the configuration and design according to customers' diverse requirements and the space of the customer's plant.