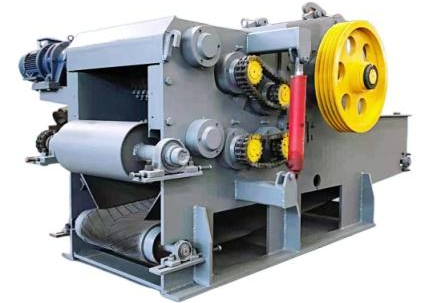

Drum Chipper Product Introduction

Scope of Application

Drum chipper series products are excellent cutting tools, crucial in multiple industries.

In the pulp and paper industry, they process wood into flaky materials for papermaking. In wood - based panel manufacturing, they provide precisely cut raw materials for high - quality panels. For biomass and power plants, they resize biomass for better energy conversion. In fuel boilers, processed materials serve as fuels for heating.

These chippers handle diverse raw materials. Wood sources like logs, bamboo, branches, bark, and residues can be processed. Non - wood materials such as sugar cane, reeds, and straw are also suitable. They're used in biomass power, pellet plants, silicon smelters, boiler enterprises, paper mills, and wood board manufacturers.

Key Points of Daily Maintenance and Functions

Thanks to its rational design, the drum chipper's components are easy to disassemble and assemble, reducing maintenance difficulty. Regularly check and replace knife - roller flying knives for good cutting. Monitor and maintain the hydraulic system's oil. Clean the conveyor belt to avoid material build - up. These steps ensure long - term stable operation and more value for the enterprise.

Product Details

Product Configuration

FD216 | FD218 | FD2111 | FD2113 |

Admission method: belt | Admission method: belt | Admission method: belt | Admission method: belt |

Main power: 55KW | Main power: 110KW | Main power: 160KW | Main power::200-220KW |

Feeding motor: 3 + 4KW | Feeding motor:4+5.5KW | Feeding motor:5.5+7.5KW | Feeding motor:5.5+7.5KW |

Discharge motor: 2.2 + 4KW | Discharge motor:2.2+4KW | Discharge motor:4+5.5KW | Discharge motor:4+5.5KW |

Knife roller form: 2-5 flying knives | Knife roller form:2-5 flying knives | Knife roller form: flying knives | Knife roller form: flying knives |

Discharge: 10-12 meters | Discharge: 10-13 meters | Discharge: 10-14 meters | Discharge: 10-15 meters |

Discharge particle size: 3-5cm | Discharge particle size: 3-6cm | Discharge particle size: 3-7cm | Discharge particle size: 3-8cm |

Output: 6-8T/H | Output:8-10T/H | Output:15-18T/H | Output:18-22T/H |

Product Service

Company Profile

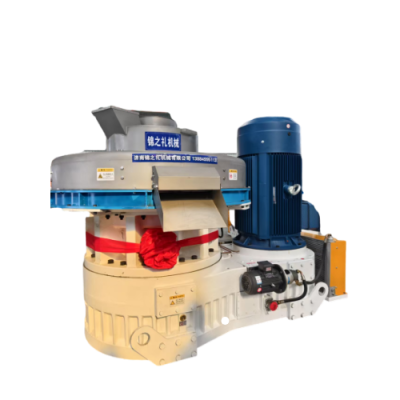

Our firm holds the belief that quality and efficiency are the cornerstones for an enterprise's establishment, and service and quality are the catalysts for an enterprise's progress. The product series features wood chip pellet machines, straw pellet machines, biomass pellet machines, sludge briquetting machines, air flow and drum series drying equipment. Moreover, we have cutting and crushing series equipment, and a full set of biomass pellet production line equipment, like other auxiliary cooling, screening, packaging, and conveying equipment. The company's technical personnel will customize and plan the equipment based on the different demands of customers and the actual space of their factory buildings.