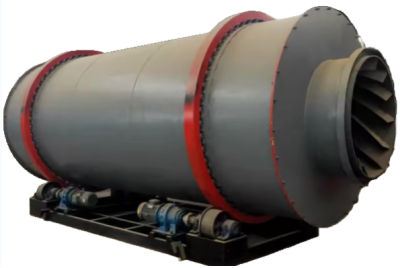

Drum Chipper Product

Product features:

Stable structure, high production capacity and low processing cost.

The size of the feed port is large, which is convenient for materials to enter and increases the production capacity.

The number of rotor blades is adjustable, and the material is uniform after crushing.

The material has a wide range of adaptability and is not limited by moisture.

Drum Chipper Product Introduction

Scope of Application

Drum chipper series products are high-quality cutting tools renowned for their outstanding performance, playing a pivotal role in multiple industrial sectors. In the pulp and paper industry, they can efficiently process diverse wood raw materials into flaky materials that meet the strict requirements of the papermaking process, thereby providing a stable and reliable source of raw materials for paper production. In the manufacturing of wood-based panels, whether it's plywood, particleboard, or fiberboard, the precisely cut raw materials by drum chippers lay a solid foundation for the quality of these panels. For biomass pellets and biomass power plants, drum chippers transform various biomass raw materials into appropriate sizes, which significantly improves the conversion efficiency and combustion effect of biomass energy. In the field of fuel boilers, the processed materials can serve as efficient fuels to meet the heating demands of both industrial and civil applications.

As specialized equipment, drum chippers can handle a wide array of raw materials. Regarding wood raw materials, logs can be swiftly cut, converting thick timber into flakes that conform to production requirements. Bamboo, with its unique properties, can be widely utilized in the papermaking and bamboo fiber product industries after being processed by a drum chipper. The effective utilization of branches has always been a key aspect of resource recycling, and drum chippers can turn them into valuable resources. Tree bark, slats, round wood cores, and wood processing residues can also be processed by drum chippers to become valuable production raw materials. Non-wood raw materials such as sugar cane can be used for biomass energy or related industrial product production after processing. Reeds, straw, etc., which are of great significance in agricultural resource utilization and environmental protection, can be transformed into usable forms by drum chippers. These products are widely applied in many industries, including biomass power plants, biomass pellet plants, silicon smelters (used to supply auxiliary fuels or insulation materials, etc.), boiler combustion enterprises, paper mills, and composite wood board manufacturing plants.

Key Points of Daily Maintenance and Functions

In terms of daily maintenance, due to the reasonable structural design of the drum chipper, all components are easy to disassemble and install, greatly reducing the maintenance difficulty. Regularly check and replace the flying knives on the knife roller to ensure cutting performance; check the oil level and oil quality of the hydraulic system and replenish and replace the hydraulic oil in a timely manner; clean and maintain the conveyor belt to prevent material accumulation from affecting the conveying effect. These simple maintenance measures can ensure the long - term stable operation of the drum chipper and create greater value for the enterprise.

Product Details

The drum chipper is mainly made up of the body, knife roller, upper and lower feeding rollers, conveyor belt, and hydraulic system. The body, welded with high-strength steel plates, offers stable support for long-term, high-intensity operation.

The knife roller, a core part, has two flying knives made of special alloy steel. Fixed firmly with bolts and pressure blocks, they can cut various hard raw materials efficiently with uniform cut sizes.

The upper feeding roller can be adjusted up and down via the hydraulic system according to raw material thickness. Advanced control technology allows for intelligent adjustment, enhancing applicability and production efficiency.

Qualified flaky materials fall through the sieve made of high-strength stainless steel and are collected, while unqualified ones are recut until they meet the size requirements.

The hydraulic system uses a hand oil pump for oil supply, making it easy to open the machine cover, replace blades, adjust the knife gap, and disassemble/assemble the comb plate, thus improving maintenance convenience and working efficiency.

In a biomass power plant, it boosts processing efficiency by 30% and improves combustion effects. In a wood-based panel manufacturing enterprise, it ensures the quality of flaky materials, enhancing the strength and flatness of wood-based panels.

| FD216 | FD218 | FD2111 | FD2113 |

| Admission method: belt | Admission method: belt | Admission method: belt | Admission method: belt |

| Main power: 55KW | Main power: 110KW | Main power: 160KW | Main power::200-220KW |

| Feeding motor: 3 + 4KW | Feeding motor:4+5.5KW | Feeding motor:5.5+7.5KW | Feeding motor:5.5+7.5KW |

| Discharge motor: 2.2 + 4KW | Discharge motor:2.2+4KW | Discharge motor:4+5.5KW | Discharge motor:4+5.5KW |

| Knife roller form: 2-5 flying knives | Knife roller form:2-5 flying knives | Knife roller form: flying knives | Knife roller form: flying knives |

| Discharge: 10-12 meters | Discharge: 10-13 meters | Discharge: 10-14 meters | Discharge: 10-15 meters |

| Discharge particle size: 3-5cm | Discharge particle size: 3-6cm | Discharge particle size: 3-7cm | Discharge particle size: 3-8cm |

| Output: 6-8T/H | Output:8-10T/H | Output:15-18T/H | Output:18-22T/H |

After - Sales Service

We are deeply aware that the stable operation of the equipment is of vital importance to your business. Therefore, we have established a professional and efficient after - sales team to safeguard your use of the drum chipper.

Rapid Response Mechanism: The after - sales team is on standby 24 hours a day, 365 days a year. When you encounter any equipment problems and provide feedback, we promise to respond within 1 hour, getting in touch with you via phone, email, or online communication platforms to understand the details of the malfunction.

Professional Technical Support: Team members all have rich mechanical maintenance experience and have a profound understanding of the structural principles and common fault handling methods of drum chippers. For the problems you describe, they can quickly make a preliminary diagnosis and provide detailed solutions. Whether it's daily maintenance consultation for the equipment or emergency handling of sudden failures, we can offer professional guidance.

On - site Maintenance Service: If the problem cannot be resolved through remote guidance, we will arrange the nearest after - sales engineer to go to the site according to your location.. The engineer will carry complete professional maintenance tools and common spare parts to ensure the on - site quick repair of the equipment and reduce downtime.

Original Factory Spare Parts Supply: To ensure the performance and service life of the equipment, all replacement parts we provide are produced by the original factory, with reliable quality and excellent compatibility with the equipment. During the maintenance process, we strictly follow the original factory maintenance standards and procedures to ensure that the equipment is restored to its original state after maintenance.

Regular Follow - up and Maintenance Reminder: After the equipment is delivered and put into use, the after - sales team will regularly visit you to understand the operation status of the equipment and collect your usage opinions and suggestions. At the same time, according to the running time and working intensity of the equipment, we will timely remind you to carry out necessary maintenance, such as replacing vulnerable parts and checking the wear of key components, to extend the service life of the equipment and reduce the probability of failures.

Training Service: To help your operators better use and maintain the drum chipper, we provide free operation training and maintenance training. The training content includes the correct operation method of the equipment, daily maintenance points, common fault troubleshooting, etc., to ensure that your team is proficient in equipment use skills and can fully utilize the equipment's performance.

Free Technical Support and Warranty Maintenance: We offer free technical support. The entire machine comes with a one - year warranty (excluding auxiliary equipment, excluding artificial damage and replacement of vulnerable parts), and we provide lifetime maintenance. This means that within one year from the date of purchase, if there are any quality problems with the main body of the machine (excluding the excluded parts), we will repair or replace it free of charge. After the one - year warranty period, we will still provide maintenance services for the machine, ensuring that your equipment can operate stably for a long time.