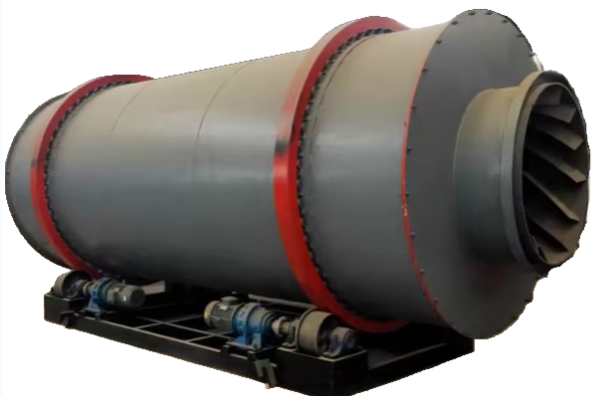

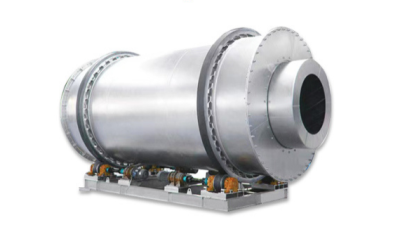

Golden Equation Industrial Three-drum dryer

1.Large drying capacity: capable of handling large quantities of wet materials, enhancing work efficiency.

2.Smooth operation: the equipment runs smoothly, reducing the failure rate and ensuring continuous operation.

3.Low energy consumption: save energy, reduce production cost.

4.Convenient operation: simplify the operation process, easy to use and maintain.

5.High output: high production efficiency, able to meet the needs of large-scale production.

The High - performance Three - Cylinder Dryer efficiently dries wet materials like powder, granules, and small lumps. It's widely used in energy, fertilizer, chemical, and pharmaceutical industries. Noteworthy features include large drying capacity, stable operation, low energy consumption, easy operation, and high output.

Feeding:Wet materials enter via a feeding device. The speed and quantity can be adjusted to ensure a steady material supply for production needs.

Heating:Heating elements or hot air channels inside the cylinders raise the temperature. Precise temperature control meets different materials' drying requirements.

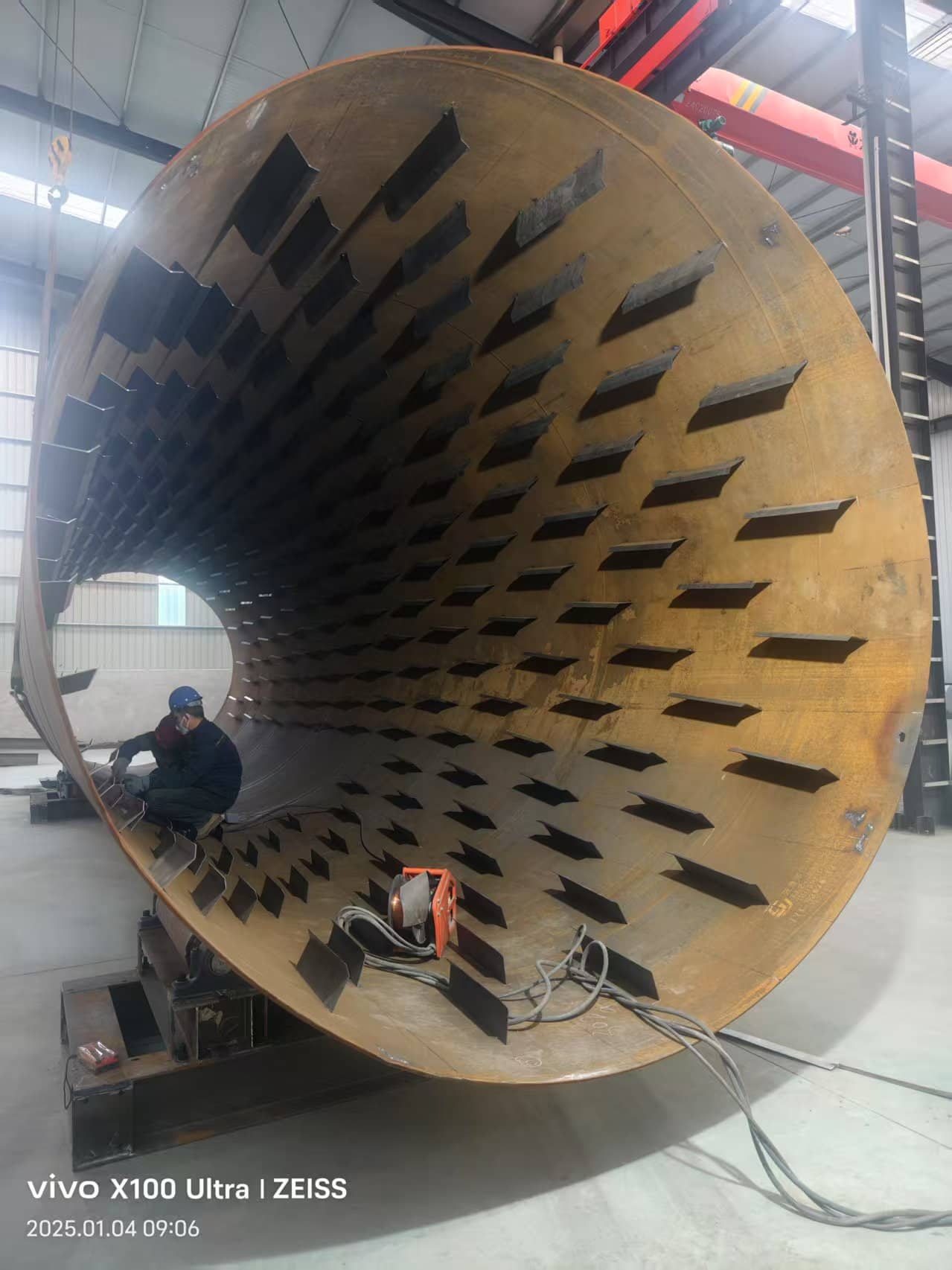

Drying:As the cylinders rotate, internal blades tumble materials, evenly exposing them to hot air. This enables efficient heat and mass transfer, evaporating moisture carried away by hot air.

Exhausting:Moist air with evaporated water is discharged through an exhaust system with filters to remove impurities and meet environmental standards.

Discharging:Once materials reach the right moisture level, they're discharged. They can then be collected for further processing or storage.

In summary, the Three - cylinder dryer uses cylinder rotation and hot air for drying. Its high efficiency, energy - saving, and uniform drying make it ideal for industrial applications.

Product Features of the Drum Dryer

High Drying Capacity:Can handle large volumes of wet materials, greatly enhancing work efficiency for high - volume production.

Smooth Operation:Well - designed structure ensures smooth running, reduces failure rate, and guarantees continuous operation, crucial for minimizing industrial downtime.

Low Energy Consumption:Utilizes advanced design and energy - efficient tech to cut energy use, saving resources and slashing production costs.

Convenient Operation:User - friendly design with simple control systems makes operation and maintenance easy, requiring little technical know - how.

High Output:Capable of high - level output, ensuring high production efficiency to meet large - scale production demands.

Company Profile

Our company offers a diverse range of products. These include wood pellet machines, straw pellet machines, biomass pellet machines, sludge briquetting machines, as well as airflow and drum - type drying equipment in the drying series. In the cutting and crushing category, we have a series of relevant equipment. Additionally, we provide ancillary cooling equipment, screening equipment, packaging equipment, and conveying equipment, thus presenting a complete set of biomass pellet production line equipment.

Our company's technical team is dedicated to custom - configuring and designing solutions. They take into account the unique requirements of each customer, along with the available plant space at the customer's site, to ensure that the equipment and production line setups are perfectly tailored to meet the customers' specific needs.