Product Introduction

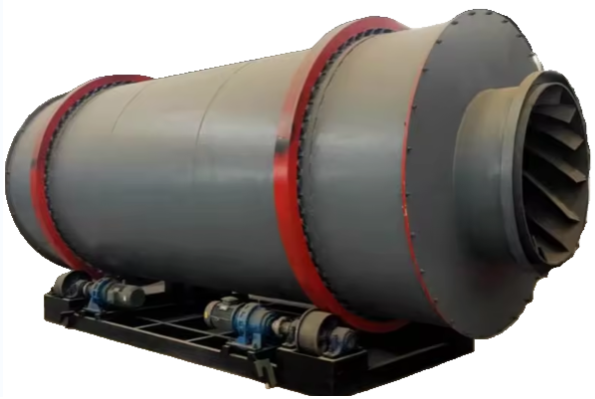

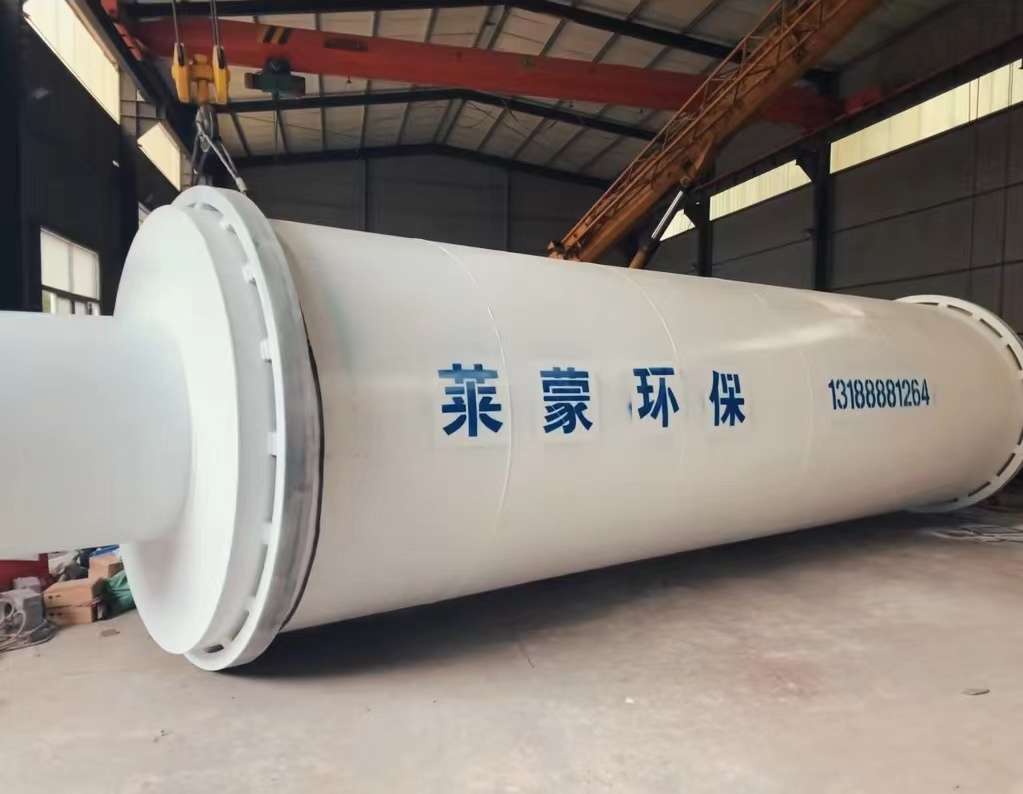

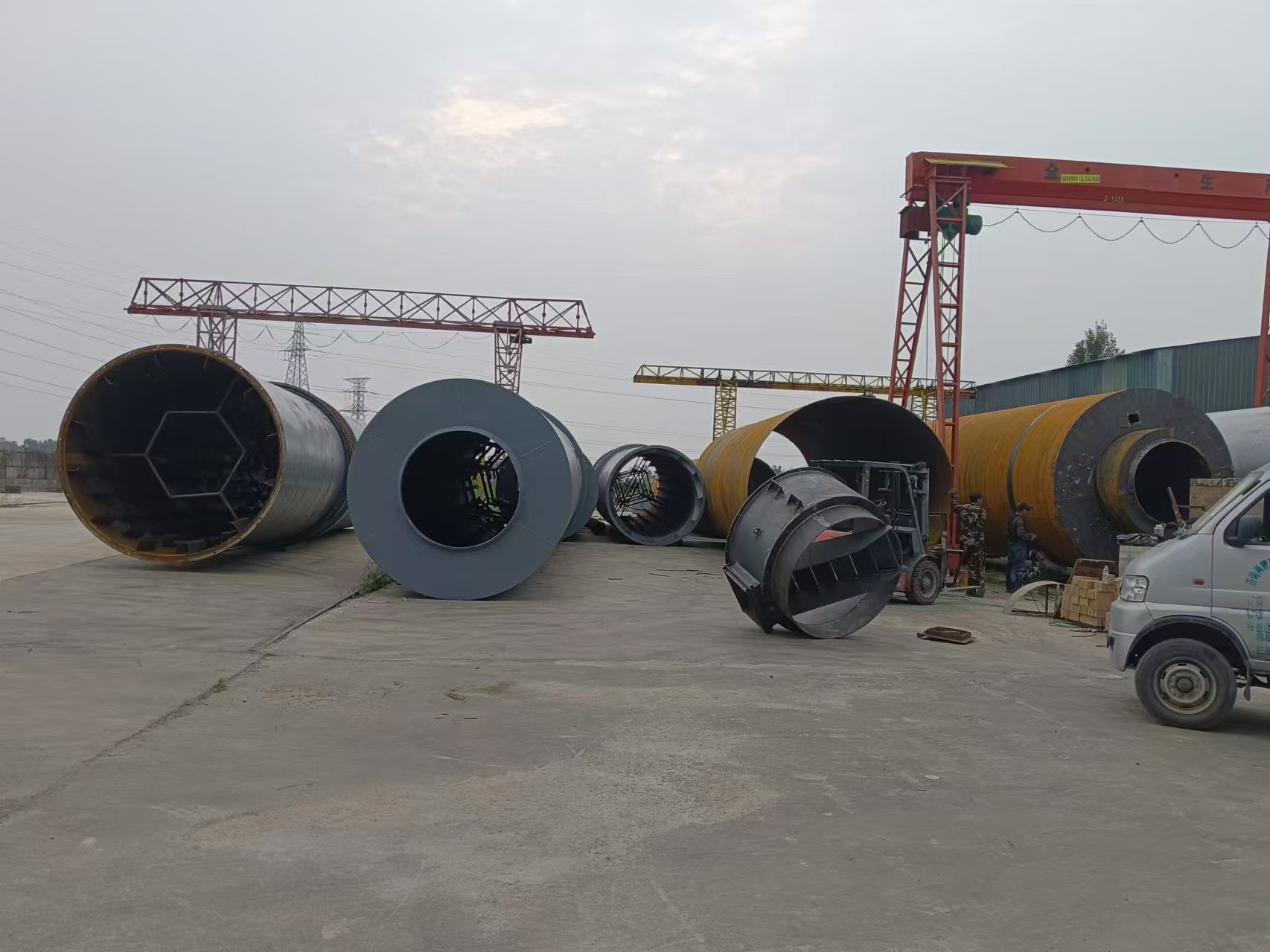

The rotary dryer mainly consists of a cylinder, a roller ring, a base retaining roller, and a tail dust - removing device. Inside the cylinder, hot air contacts the material. The material is arranged to ensure full contact with hot air for drying.

Single - Cylinder Dryer series products are mainly for drying wet materials like powders, granules, and small lumps. They are widely used in energy, fertilizer, chemical, and pharmaceutical sectors.

Usage in Biomass Granulation

During biomass granulation, if raw material moisture doesn't meet requirements, drying is needed. The drum dryer, a commonly used drying device, can dry wood chips, straw, rice, etc. It's easy to operate and runs stably.

Working Principle

Hot air enters the dryer cylinder from the hot air furnace.

Material enters from the inlet.

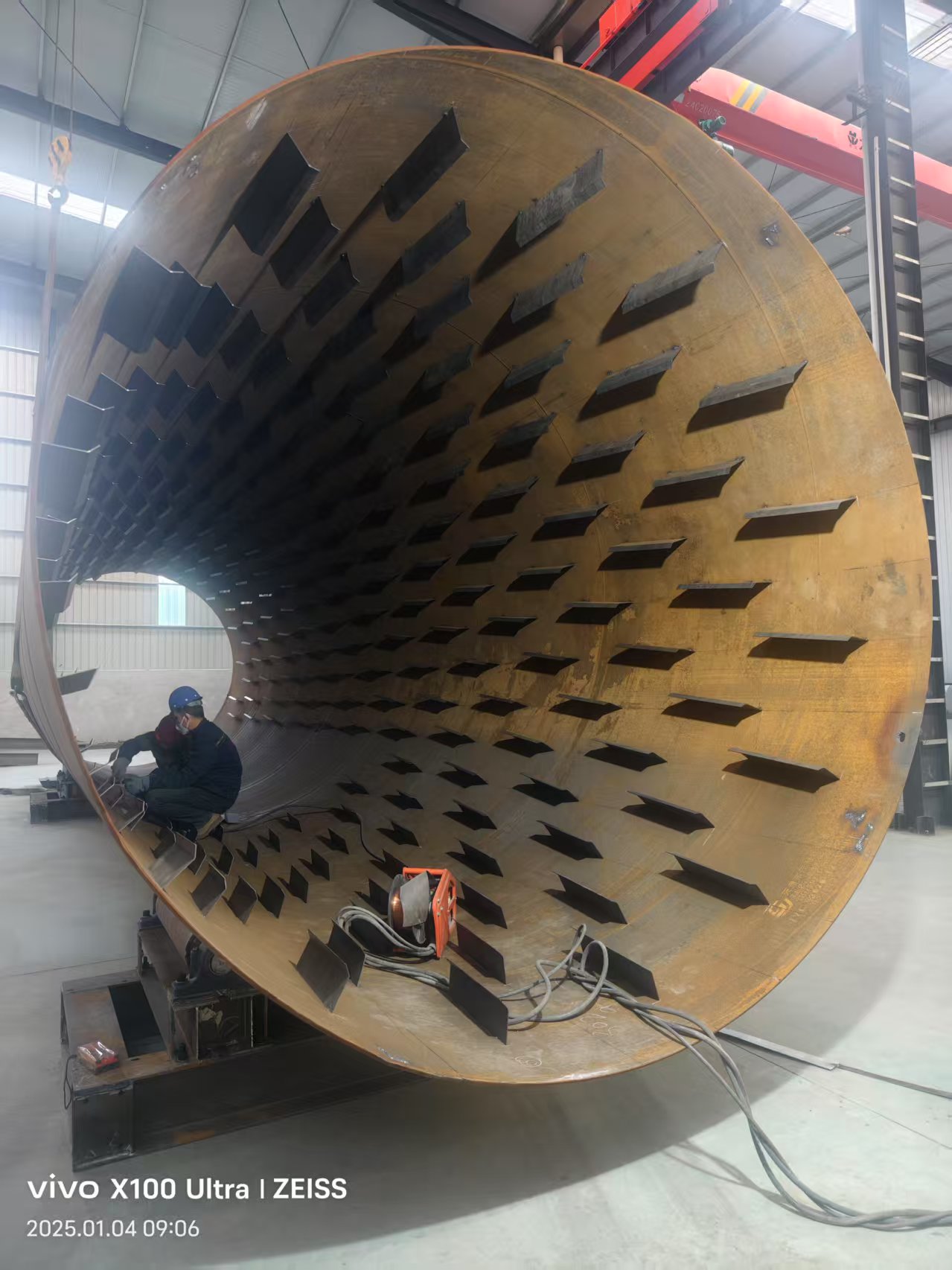

The lifting board in the dryer lifts the material.

Hot air contacts the material and removes its water.

Material exits from the discharge port, and hot air is drawn from the upper end.

Material movement mainly depends on the lifting board's propelling effect.

Equipment Configuration

The drum dryer alone can't work. It generally requires a heat source (hot air furnace), fans, a shakelong, and sometimes dust - removal equipment.

Component Composition

The drum dryer is made up of a cylinder, inlet, outlet, toothed ring, and aperture.

Product features

1. The drum dryer has a large drying capacity, capable of handling large quantities of wet materials, enhancing work efficiency.

2. The drum dryer operates smoothly, reducing the failure rate and ensuring continuous operation.

3. The drum dryer features low energy consumption, saving energy and reducing production costs.

4. The drum dryer offers convenient operation, simplifying the process and making it easy to use and maintain.

5. The drum dryer delivers high output, ensuring high production efficiency and meeting the needs of large-scale production.

Parameter

Type | Model | Configuration | Evaporation(T/H) |

Single-cylinder dryer | HYHGφ1.5-12m | Main machine(7.5kw);Fan(15kw);Shaklon(φ1400);Electric control cabinet; | 0.5-0.75 |

HYHGφ1.5-15m | Main machine(11kw);Fan(18.5kw);Shaklon(φ1500);Electric control cabinet; | 0.5-0.75 | |

HYHGφ1.6-18m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 0.7-1 | |

HYHGφ1.8-15m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 1-1.3 | |

HYHGφ1.8-18m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 1-1.3 | |

HYHGφ2.0-20m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.4-2.0 | |

HYHGφ2.0-24m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.4-2.0 | |

HYHGφ2.2-24m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.7-2.5 | |

HYHGφ2.4-24m | Main machine(22kw);Fan(37kw);Shaklon(2-φ1500);Electric control cabinet; | 2.2-3 | |

HYHGφ2.8-24m | Main machine(30kw);Fan(55kw);Shaklon(4-φ1200);Electric control cabinet; | 2.5-3.6 | |

HYHGφ2.2-8-Ⅲ | Main machine(12kw);Fan(45kw);Shaklon(2-φ1200);Electric control cabinet; | 1.3-1.8 | |

HYHGφ2.4-9-Ⅲ | Main machine(12kw);Fan(45kw);Shaklon(2-φ1200);Electric control cabinet; | 1.6-2.5 | |

HYHGφ2.6-12-Ⅲ | Main machine(22kw);Fan(55kw);Shaklon(2-φ1400);Electric control cabinet; | 2.0-2.8 | |

HYHGφ2.8-12-Ⅲ | Main machine(22kw);Fan(55kw);Shaklon(2-φ1400);Electric control cabinet; | 2.1-3.0 | |

HYHGφ3.0-12-Ⅲ | Main machine(30kw);Fan(75kw);Shaklon(2-φ1500);Electric control cabinet; | 2.4-3.5 | |

HYHGφ3.2-12-Ⅲ | Main machine(30kw);Fan(90kw);Shaklon(2-φ1500);Electric control cabinet; | 3.0-5.0 |

Company Profile

Series of products are: wood pellet machine, straw pellet machine, biomass pellet machine, sludge briquetting machine, airflow, drum series drying equipment; cutting, crushing series of equipment, and other ancillary cooling equipment, screening equipment, packaging equipment, conveying equipment, such as a full set of biomass pellet production line equipment. The company's technical personnel according to the different needs of customers and customer plant space for customized configuration and design.