850 Type 250KW Wood Pellet Machine

Supply Ability & Additional Information

Packaging: shipping by container

Productivity: 2.5-3.5 T/H

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 50 set per month

Port: Qingdao, Shanghai, etc.

Payment Type: L/C,T/T,D/P,Western Union

Incoterms: FOB,CFR,CIF,EXW

Packaging & Delivery

Selling Units: Set/Sets

Package Type: shipping by container

Container types: 40HQ/40FR (flat rack container), with support for oversized cargo transportation.

Compliance Documents:

Can provide Certificate of Origin (CO), preferential origin certificates such as FORM E/F

(entitling tariff reductions in the importing country);

Support shipping with certification documents such as ISO, CE, FDA

(advance declaration of certification requirements is required).

Parameter

Category | Model | Power(KW) | Pellet size(mm) | Output(t/h) | Overall Dimension(mm) | Machine Weight(T) |

Vertical ring mould | JL560 | 132/160 | 6-12 | 1.5-2 | 2200*1280*1640 | 5T-5.5T |

JL2-850 | 250 | 6-12 | 3.0-4.0 | 2800*1720*2130 | 10.7T | |

JL2-850 | 280/315 | 6-12 | 4.0-5.0 | 2800*1720*2130 | 13.5T |

1. Product Overview

The 850 Type Wood Pellet Machine is a high - performance biomass granulation equipment designed to transform a variety of biomass materials into high - density pellets. With a production capacity ranging from 3 to 5 tons per hour (T/H), it is suitable for both small - scale enterprises and large - scale industrial production.

2. Key Features

High - Capacity Production

Equipped with a powerful motor and optimized mechanical structure, the 850 Type Wood Pellet Machine can achieve a high output of 2.5 - 3.5 T/H, meeting the needs of large - volume biomass pellet production. This high productivity helps users quickly recover their investment and gain a competitive edge in the market.

Wide Range of Applicable Materials

This machine is versatile and can process a variety of biomass materials, including sawdust, wood chips, bamboo chips, bark, agricultural residues such as rice husks, peanut shells, sunflower husks, and various crop stalks. It can handle materials with low adhesion rates, making it an ideal choice for processing hard - to - shape biomass resources.

Stable and Durable Performance

The machine's main components, such as the gearbox, ring die, and rollers, are made of high - quality materials. The gearbox adopts a multi - stage gear reduction design, which provides high torque and stable operation. The ring die is made of wear - resistant stainless steel and processed by advanced methods like vacuum quenching, ensuring a long service life. The rollers are also designed with special wear - resistant alloys or surface treatment to withstand abrasion during the granulation process.

Energy - Efficient Operation

Despite its high production capacity, the 850 Type Wood Pellet Machine is designed with energy - saving in mind. The optimized mechanical transmission system reduces energy loss, and the intelligent control system can adjust the operating parameters according to the material characteristics, achieving efficient energy utilization and reducing production costs.

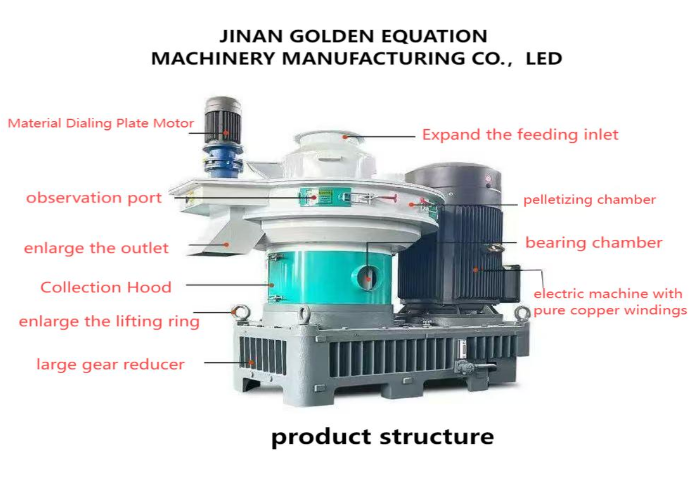

3. Working Principle

The working process of the 850 Type Wood Pellet Machine is as follows:

Feeding

The prepared biomass materials are fed into the machine through a feeding system. The feeding system is designed to ensure a continuous and stable feed rate, which is crucial for the smooth operation of the granulation process.

Compression and Granulation

Inside the machine, the materials are first pre - pressed and then forced through the holes of the ring die by the rotating rollers. The high pressure during this process compresses the biomass materials into dense pellets. The diameter of the pellets can be adjusted according to individual needs, usually available in sizes such as 6mm, 8mm, and 10mm.

Discharging

The formed pellets are discharged from the machine and then can be further processed, such as cooling, screening, and packaging.

Company Profile

The company focuses on cultivating long-term customer relationships, with high quality products and scrupulous dedication to accompany and witness the growth of many of our customers. We firmly believe that there is a market only with quality and a reputation only with service. Quality and efficiency are the fundamentals to win a foothold in the enterprise, and service and reputation are the keys to win the progress of the enterprise.