High Efficiency Grinder

High Efficiency and High Yield:High-performance motor and precise mechanism enable fast, high-output grinding, cutting time and boosting profits.

Durable and Easy to Maintain:Quality materials and sturdy build, plus quick-release design, ease maintenance and reduce downtime.

Energy Saving and Consumption Reduction:Optimized system cuts energy use, with smart control saving costs sustainably.

Scientific Working Process:Well-designed stages—feeding, grinding, screening—guarantee smooth, reliable operation.

Wide Material Compatibility:Handles diverse materials, from hard minerals to soft organics, serving multiple industries.

Precise Particle Size Control:Adjustable settings ensure consistent, accurate particle fineness for all grinding needs.

The introduction of product

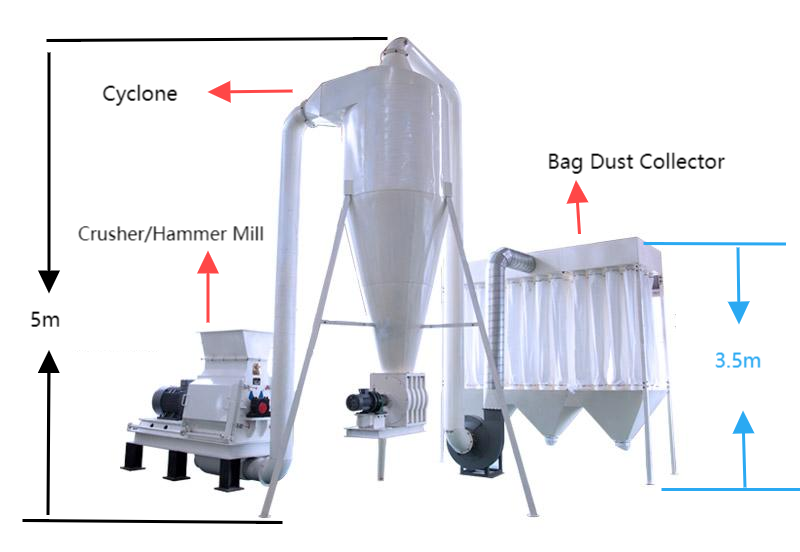

A complete set of pulverizer system includes pulverizer host, fan, cyclone separator (Shakron), air lock valve, bag dust collector, and other essential components. Before assembly, the main parts of the pulverizer—especially the rotor—undergo dynamic balance calibration to ensure stable operation and minimize vibration. Additionally, the motor base assembly platform and rotor spindle bearing seat assembly platform are machined in one-time synchronous processing using large-scale CNC machine tools. This high-precision manufacturing ensures the laptop operates with brilliant smoothness, precision, and long-term reliability, making it best for non-stop industrial grinding applications.

Parameter

Model | Power | Yield T/H | Raw Material Situation |

JLFS65*130 | 132kw | 5-6 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

JLFS75*150 | 160/200 | 7-8 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

JLFS1000-1600 | 250kw | 8-10 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

JLFS1200-1300 | 315kw | 10-15 | Wood chips Length ≤ 5 cm Thickness ≤ 0.5 cm |

Note:According to the model supporting: discharge auger fan, dust collector, Shaklon, air closure, piping, inlet and outlet belts, electric control cabinet. | |||

High-Efficiency Pulverizer System for Industrial Grinding

Your Reliable Solution for Precise and High-Volume Material Processing

Product Overview

Our high-efficiency pulverizer system is a cutting-edge industrial grinding solution designed to transform various materials into fine powders or granules with exceptional precision and productivity. Engineered for durability and performance, the complete set includes:

Pulverizer Host: The core unit with a robust rotor and dynamic balance calibration for stable, low-vibration operation.

Fan & Cyclone Separator (Shakron): Efficient material conveying and separation to maximize output efficiency.

Air Lock Valve: Ensures controlled discharge while preventing air leakage.

Bag Dust Collector: Complies with environmental standards by minimizing dust emissions.

Key Technical Advantages

Precision Manufacturing

Rotor and critical components undergo rigorous dynamic balance testing to eliminate operational instability.

Motor base and bearing seats are machined using large-scale CNC machine tools in one-time synchronous processing, ensuring ultra-high alignment accuracy and minimal mechanical wear.

High Efficiency & Versatility

Handles a wide range of materials: Hard minerals (e.g., quartz, limestone), organic substances (e.g., herbs, biomass), chemicals, plastics, and more.

Adjustable grinding settings allow particle size control from coarse (100 mesh) to ultra-fine (800 mesh), meeting diverse industry requirements.

Capable of continuous operation with throughputs ranging from5 to 15 tons per hour (customizable based on models).

Energy-Efficient & Environmentally Friendly

Optimized motor and airflow design reduces energy consumption by up to 20% compared to traditional models.

Integrated bag dust collector ensures compliance with international environmental regulations (e.g., CE, ISO 14001), making it suitable for eco-conscious markets.

Easy Maintenance & Long Service Life

Quick-release structures for easy access to the grinding chamber, simplifying cleaning and component replacement.

Wear-resistant alloys and anti-corrosive coatings on key parts (e.g., rotor blades, cyclone inner walls) extend service life even under heavy-duty conditions.

Company Profile

Located at No. 10, Jinshan West Road, Taohuashan Industrial Park, Xiuhui Town, Zhangqiu District, Jinan City, Shandong Province, Jinan Jinfangcheng Machinery Manufacturing Co., Ltd is a production-oriented enterprise founded in 2019 in Zhangqiu District, Jinan City, Shandong Province. The company is a comprehensive enterprise engaged in the design and development of mechanical equipment, manufacturing and international trade in one. The company's products are mainly involved in environmental protection and low carbon, biomass energy, urban and rural environment construction and other industry fields. Product series include biomass compression molding equipment, organic fertilizer equipment and urban and rural garbage treatment equipment and environmental protection dust removal equipment and other series. Favored by the domestic and foreign and the industry.