High Capacity Ring Die Wood Pellet Mill

Powerful & Efficient

Heavy-duty motor and gear system for non-stop operation

High-density, uniform pellets with 95%+ success rate

Works with Various Materials

Processes wood scraps (pine, fir, mixed) and farm waste (straw, peanut shells, hay)

Easy to Use & Maintain

Compact with auto-feeding

Modular design for quick cleaning and mold changes

Less downtime

Designed for farms, lumber mills, and biofuel entrepreneurs, our pellet mill is your key to scalable production and higher profits. Known for its reliable performance and high capacity, it efficiently transforms wood scraps, straw, rice husks, and other biomass into valuable fuel or feed pellets—boosting your bottom line.

Why Choose Our Briquetting Press? — Key Advantages Explained

We engineer every detail to address the pain points of traditional equipment, ensuring your investment delivers long-term value.

1. Innovative Direct-Drive System: Maximum Power, Unmatched Efficiency

Feature: Motor is directly flanged to the reducer gearbox, eliminating inefficient belt/chain drives.

Your Benefits:

Kinetic Energy Conversion >95%: Minimal power loss, translating electrical energy directly into compaction force.

Significantly Higher Output: Faster cycle times and greater instantaneous pressure boost your production line capacity.

Reduced Energy Consumption: Higher efficiency means lower electricity bills for the same output.

Simplified Maintenance: Fewer moving parts reduce potential failure points and maintenance costs.

2. Super-Durable Press Wheel & 3-Stage Gear Reducer: Extreme Load Capacity, Extended Lifespan

Materials & Craftsmanship:12

Press Wheel: Utilizes a super wear-resistant alloy hard-facing welding technique, achieving a surface hardness over HRC 60+, far surpassing traditional surface carburization.

Gear Reducer: Features a three-stage, heavy-duty gear design made from high-strength alloy steel, precision carburized, quenched, and ground. Load capacity is increased by approximately 40%.

Your Benefits:

2-3X Longer Press Wheel Life: Drastically reduces replacement frequency and spare part costs.

Enhanced Mold Protection: The uniformly hard surface minimizes wear and impact on the more expensive mold, protecting your critical assets.

Handles Heavy Loads with Ease: Maintains stable pressure and consistent operation even with high-density, challenging materials.

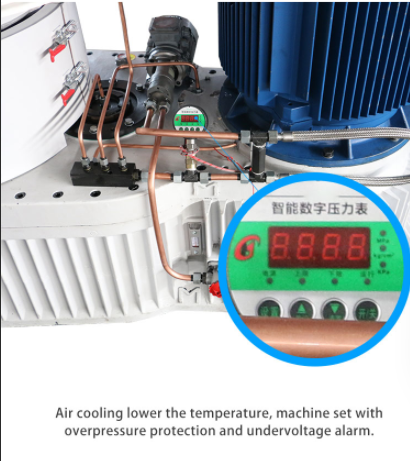

3. Integrated Lubrication & Cooling System: Uninterrupted Operation, Guaranteed Reliability

Feature: Built-in system continuously cools and filters the gear oil during operation.

Your Benefits:

Constant Temperature Protection: Keeps gears and bearings at their optimal operating temperature, preventing oil degradation and component wear.

True 24/7 Continuous Production: Enables non-stop operation to meet urgent orders and peak demand periods.

Foundation of Reliability: Virtually eliminates unplanned downtime caused by transmission system overheating.

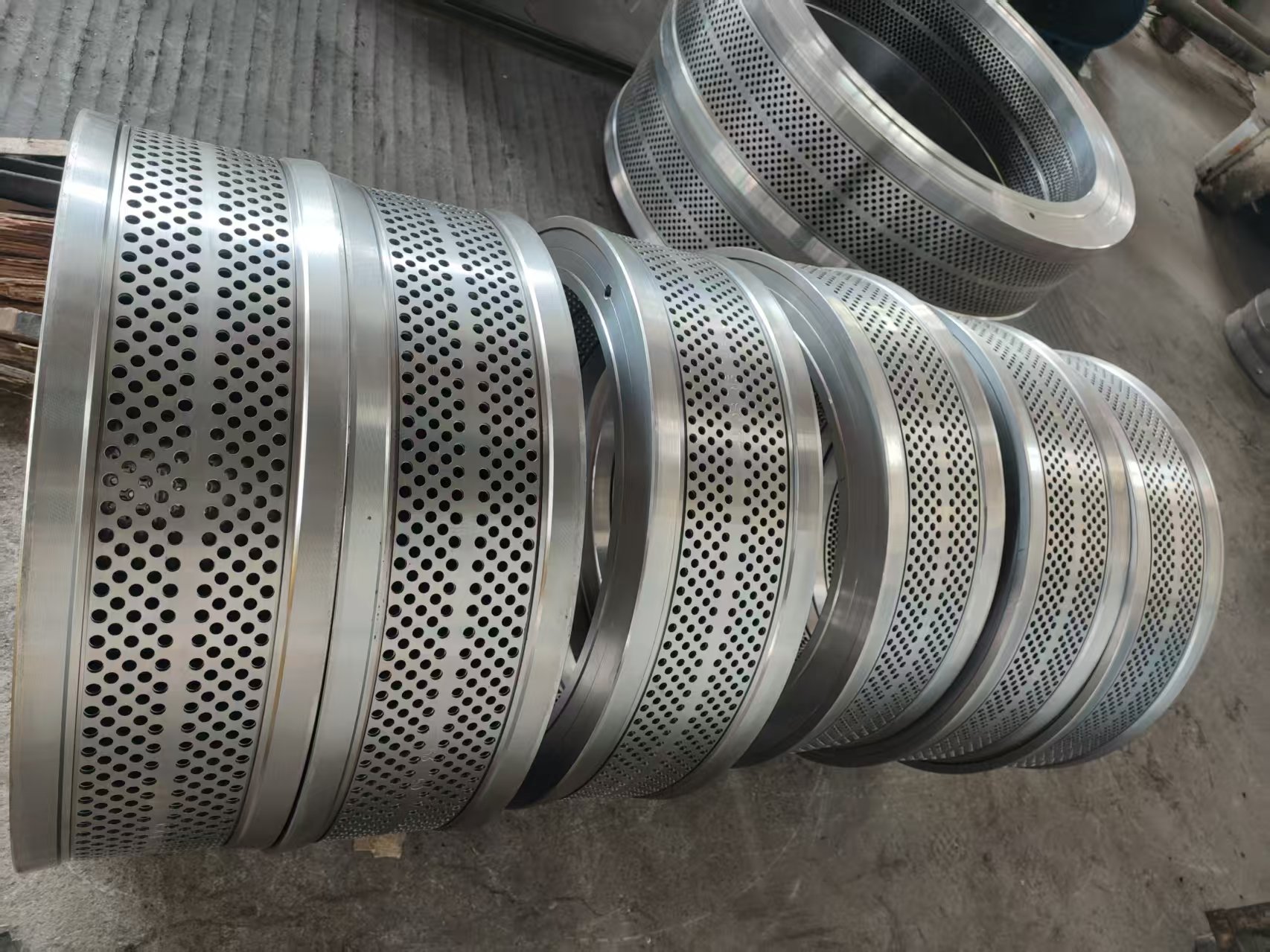

4. External Toggle System & Vacuum-Quenched Molds: Corrosion-Resistant, Crack-Proof, Consistent

Materials & Craftsmanship:

Toggle System: Externally rotating design keeps pivotal components away from high-temperature steam, effectively preventing corrosion and seizure.

Molds: Manufactured from imported wear-resistant stainless steel and treated through vacuum furnace quenching and tempering.

Your Benefits:

Exceptional Toggle System Longevity: Ensures smooth, reliable movement cycle after cycle.

Uniform Mold Hardness: Vacuum heat treatment prevents surface oxidation, resulting in consistent hardness throughout and over 50% better wear resistance.

High Resistance to Cracking: The perfect balance of toughness and hardness prevents mold breakage under impact pressure.

Consistent End-Product Quality: Stable mold performance guarantees uniform density and shape for every briquette.

Product Attributes

Model No.:GE850 | Brand:GOLDEN EQUATION |

Energy Saving:Energy Saving | Automatic Grade:Semiautomatic |

control mode:Manual control | Warranty:1Year |

Customized:Customized | Spare Parts:Roller Shell+Mould |

Moisture:13%-15% | Application:Press Wood Sawdust Into Pellets |

Motor:Chinese Famous Brand | Pellet Diameter:6-12mm Customizable |

After-sale Service:Engineers are available and they are eligible to apply for visas. | |

More Than a Product — Our Comprehensive Value & Support

Expert Customization: We tailor mold design and machine parameters for your specific material (metal chips, biomass, chemicals, etc.).

Transparent Manufacturing Process: We control the entire process—from cutting and machining to heat treatment and assembly—ensuring every machine is built to the highest standards.

Rigorous Quality Control: Every unit undergoes a 72-hour continuous no-load and load test and comes with a complete factory test report.

Proven Manufacturer Strength: As an ISO 9001 & CE certified factory with over XX years of experience, our machines are trusted by clients in over 50 countries.

Round-the-Clock Technical Support: We provide detailed installation guidance, operator training, and guaranteed rapid spare parts supply.

Contact us today for a free technical consultation and a personalized quotation!