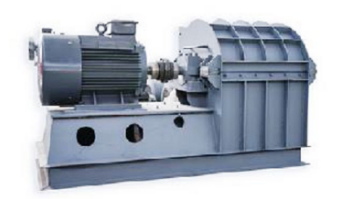

Multi Functional Milling Machine

Wearing Parts Characteristics

The four corners of the wearing parts hammer are welded with high - hardness materials such as carbon - tungsten alloy.

The thickness of the welding layer is 8mm, which effectively extends the service life.

Screen Specifications

The diameter of the bottom of the screen ranges from 6mm to 12mm. The thickness is more than 4mm.

It can be customized according to customer requirements.

Advantages of Power Connection

The motor and the hammer are directly connected through a coupling.

This connection method can save more power and improve efficiency.

Features of Discharge Design

The grinder screen consists of two parts.

After installation, the overall discharge angle is close to 360 degrees. With a large discharge area, it significantly improves production efficiency.

Crushing Effect

There are no dead - ends in the crushing process.

The particle size of the finished product is very fine.

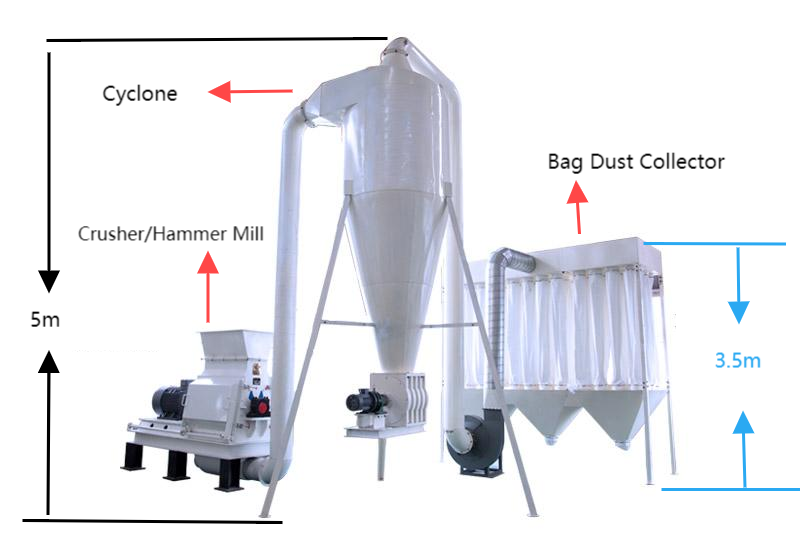

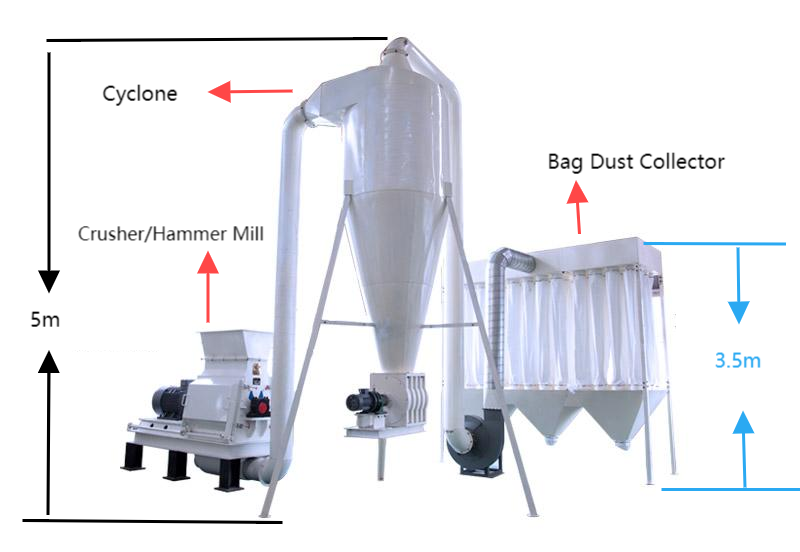

Dust Removal Configuration

Two cyclones can be equipped according to customer requirements.

The dust - containing gas is filtered through the secondary cyclone and then enters the cloth bag for dust removal, ensuring a more thorough filtration effect.

Rich Raw Material Resources

We deal with a wide variety of biological straws, such as corn straw, wheat straw, cotton straw, as well as rice straw, rice husks, peanut shells, corncobs, small pieces of wood, wood chips, branches, weeds, leaves, bamboo products and other waste materials. Among them, sawdust can be ground to a finished product size of 2 - 8mm.

Separate Raw Material Trial - Test Area

We provide our customers with a separate raw material trial - test area. In this area, we have conducted trial - tests on numerous raw materials, including but not limited to logs, wood chips, wood sawdust, rice husks, rice straw, sugarcane, palm shells, sunflower shells, construction templates, wooden pallets, and furniture waste.

Optimal Machine Recommendation

Through thousands of experimental tests on different machines, different molds with various compression ratios, we are able to offer customers the most suitable machine. This machine comes with an appropriate outer mold and the most suitable compression ratio.

model | Power (kw) | Output (T/h) | ||||||

Feed/Fertilizer | Energy | PVC | corn | feces | crude fibe | PVC (milling powder) | ||

SG40type | 7.5 | 0.3-0.8 | ф50.1-0.3 | |||||

SG50type | 15/11 | ф 2 - ф 60.5-1.0 | ф60.2-0.4 | |||||

SG65×27type (belt) | 22 | ф 2 - ф 6 0.5-2 | ф60.5-0.8 | |||||

SG65×27type (direct connection) | 22 | ф 2-ф6 1-3 | ф60.6-1.0 | |||||

SG65×55type | 55 | Suitable material | sieveф10 | |||||

SG65×55type | 55 | Suitable material | sieveф3-6 | |||||

SG65×75type | 75 | Suitable material | sieveф10 | |||||

SG65×75type | 75 | Suitable material | sieveф3-6 | |||||

SG65×100type | 90 | Suitable material | sieveф3-7 | |||||

SG65×100type | 90 | Suitable material | sieveф3-8 | |||||

WORKING PRINCIPLE

The raw material is fed through the hopper to the hammer mill. By the violent impact with the high-speed hammer, the raw material is dragged to the acceleration area where the raw material speed could be raised to the level of the hammer end line speed. The raw material will make circling motion with the hammer together, and the material converter layer appears so that the raw material could be further crushed. Finally the crushed material will be discharged out of the machine.

Company Profile

The company has the industry's leading level of machining centers, invested in a large number of high-precision production equipment production equipment, in the design of scientific research, production and manufacturing management, the company has a strong team of unity and excitement, efficient and strict. The company has won the long-term recognition of the majority of customers by virtue of its strong product development strength, exquisite design technology and scientific management, and has gained a good reputation in the industry among the existing customers.