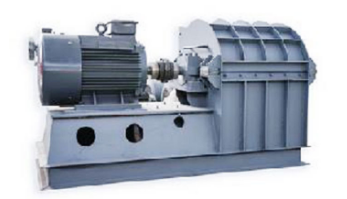

High Quality Multi Functional Milling Machine for Sale

Wearing Parts Characteristics

Screen Specifications

Advantages of Power Connection

Features of Discharge Design

Crushing Effect

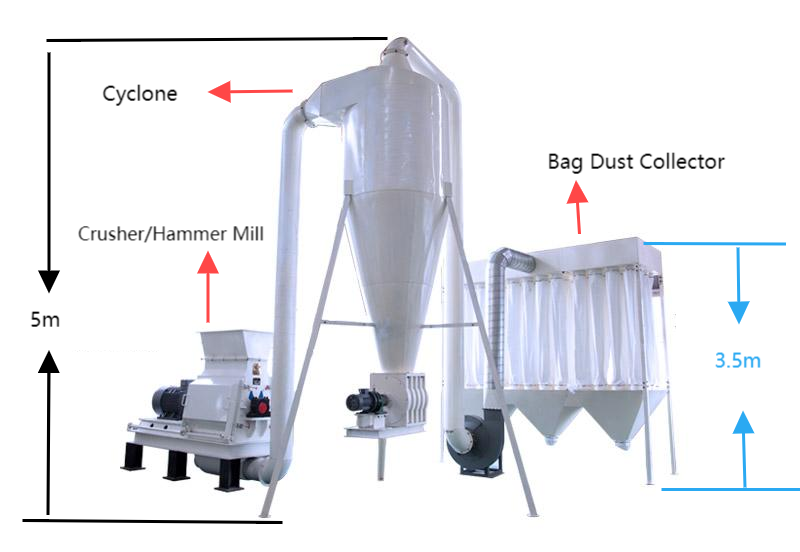

Dust Removal Configuration

High - Quality Multi - Functional Milling Machine and Raw Material Supplies

We handle an extensive range of biological straw materials and provide high - quality multi - functional milling machines. This includes corn straw, wheat straw, cotton straw, along with rice straw, rice husks, peanut shells, corncobs, small wooden pieces, wood shavings, branches, weeds, leaves, bamboo product waste, and other discarded materials. Notably, sawdust can be ground to a finished product size within the range of 2 - 8mm.

Dedicated Raw Material Testing Zone

We offer our clients a dedicated zone for raw material trial - testing. In this zone, we have carried out trial - tests on a vast number of raw materials. These raw materials include, among others, logs, wood chips, wood sawdust, rice husks, rice straw, sugarcane, palm shells, sunflower shells, construction templates, wooden pallets, and furniture waste.

Optimal Machine Recommendation

After thousands of tests on different machines and molds with varying compression ratios, we can recommend the most suitable machine to customers. This machine has an appropriate outer mold and the best - fitting compression ratio.

Our tests assess how materials interact with each machine - mold setup. For fibrous materials like wood chips or straw, a particular machine - mold combination gives better granulation. The outer mold is chosen based on material traits such as hardness, moisture, and particle size.

For fine - textured materials like sawdust, our recommended machine can grind it to 2 - 8mm precisely. The compression ratio is calibrated for efficient grinding, saving energy and increasing output.

Even for hard - to - process materials, our recommended machine and mold can handle them. By applying proper pressure and having a good mold structure, we can turn these materials into quality products. Whether for biofuel, animal feed, or other applications, our recommendation suits your needs for great results.

model | Power (kw) | Output (T/h) | ||||||

Feed/Fertilizer | Energy | PVC | corn | feces | crude fibe | PVC (milling powder) | ||

SG40type | 7.5 | 0.3-0.8 | ф50.1-0.3 | |||||

SG50type | 15/11 | ф 2 - ф 60.5-1.0 | ф60.2-0.4 | |||||

SG65×27type (belt) | 22 | ф 2 - ф 6 0.5-2 | ф60.5-0.8 | |||||

SG65×27type (direct connection) | 22 | ф 2-ф6 1-3 | ф60.6-1.0 | |||||

SG65×55type | 55 | Suitable material | sieveф10 | |||||

SG65×55type | 55 | Suitable material | sieveф3-6 | |||||

SG65×75type | 75 | Suitable material | sieveф10 | |||||

SG65×75type | 75 | Suitable material | sieveф3-6 | |||||

SG65×100type | 90 | Suitable material | sieveф3-7 | |||||

SG65×100type | 90 | Suitable material | sieveф3-8 | |||||

WORKING PRINCIPLE

The raw material is introduced via the hopper into the hammer mill. Due to the intense impact from the high - speed hammer, the raw material is drawn towards the acceleration zone. In this zone, the speed of the raw material can be elevated to the same level as the end - line speed of the hammer. The raw material then rotates in a circular motion along with the hammer, and a material converter layer is formed, enabling further crushing of the raw material. Eventually, the crushed material is ejected from the machine.

Company Profile

The company has the industry's leading level of machining centers, invested in a large number of high-precision production equipment production equipment, in the design of scientific research, production and manufacturing management, the company has a strong team of unity and excitement, efficient and strict. The company has won the long-term recognition of the majority of customers by virtue of its strong product development strength, exquisite design technology and scientific management, and has gained a good reputation in the industry among the existing customers.