Application and Function

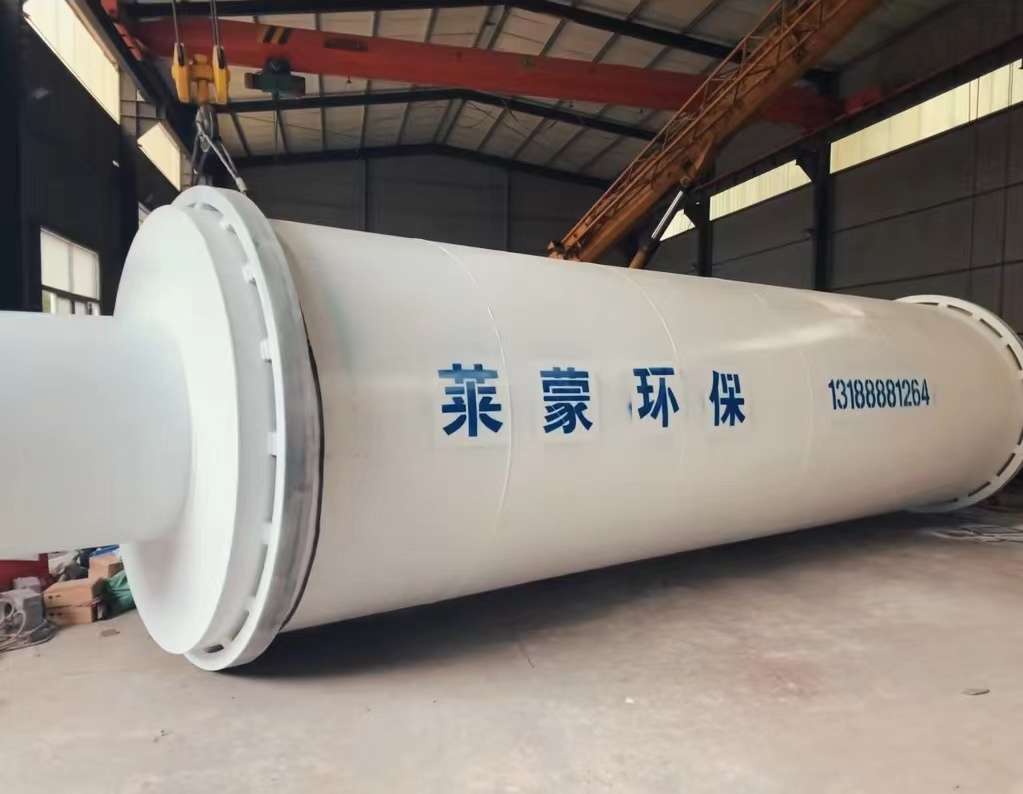

Drum dryer series products are mainly used for drying powdery, granular, small lumps and other wet materials.Widely used in energy, fertiliser, chemical and pharmaceutical industries.

Usage in Biomass GranulationIn the biomass granulation process, if the raw material moisture does not meet the granulation requirements, it needs to be dried. Drum dryer is widely used drying equipment, can dry wood chips, straw, rice and other materials. The equipment is simple to operate and stable in operation.

Working Principle

Hot air from the hot air furnace enters the dryer cylinder.

The material is fed in through the inlet.

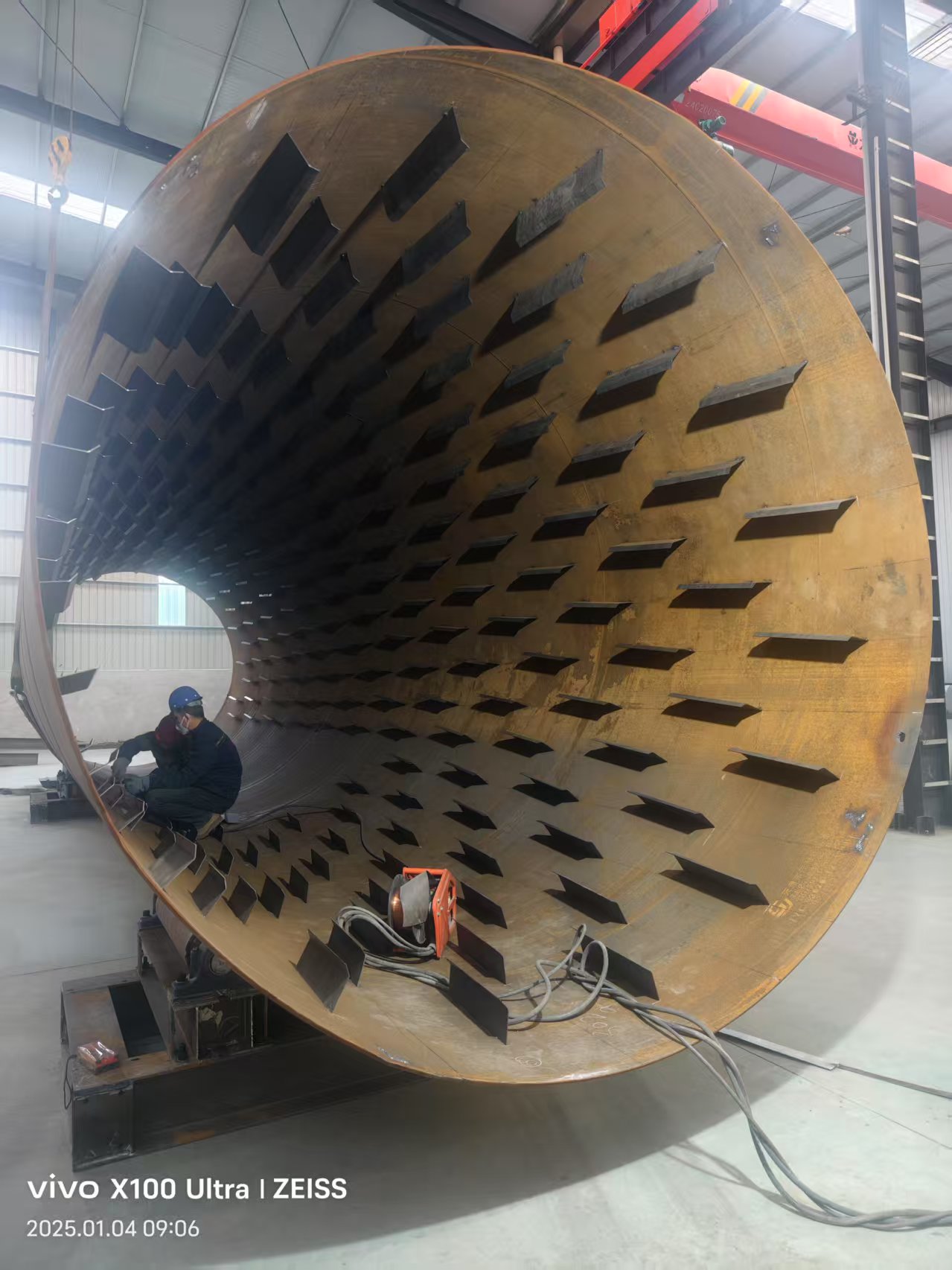

Inside the dryer, the lifting board lifts up the material.

Subsequently, the hot air makes contact with the material, removing the moisture within it.

The dried material exits from the discharge port, while the hot air is extracted from the upper end.

The movement of the material mainly depends on the pushing force exerted by the lifting board.

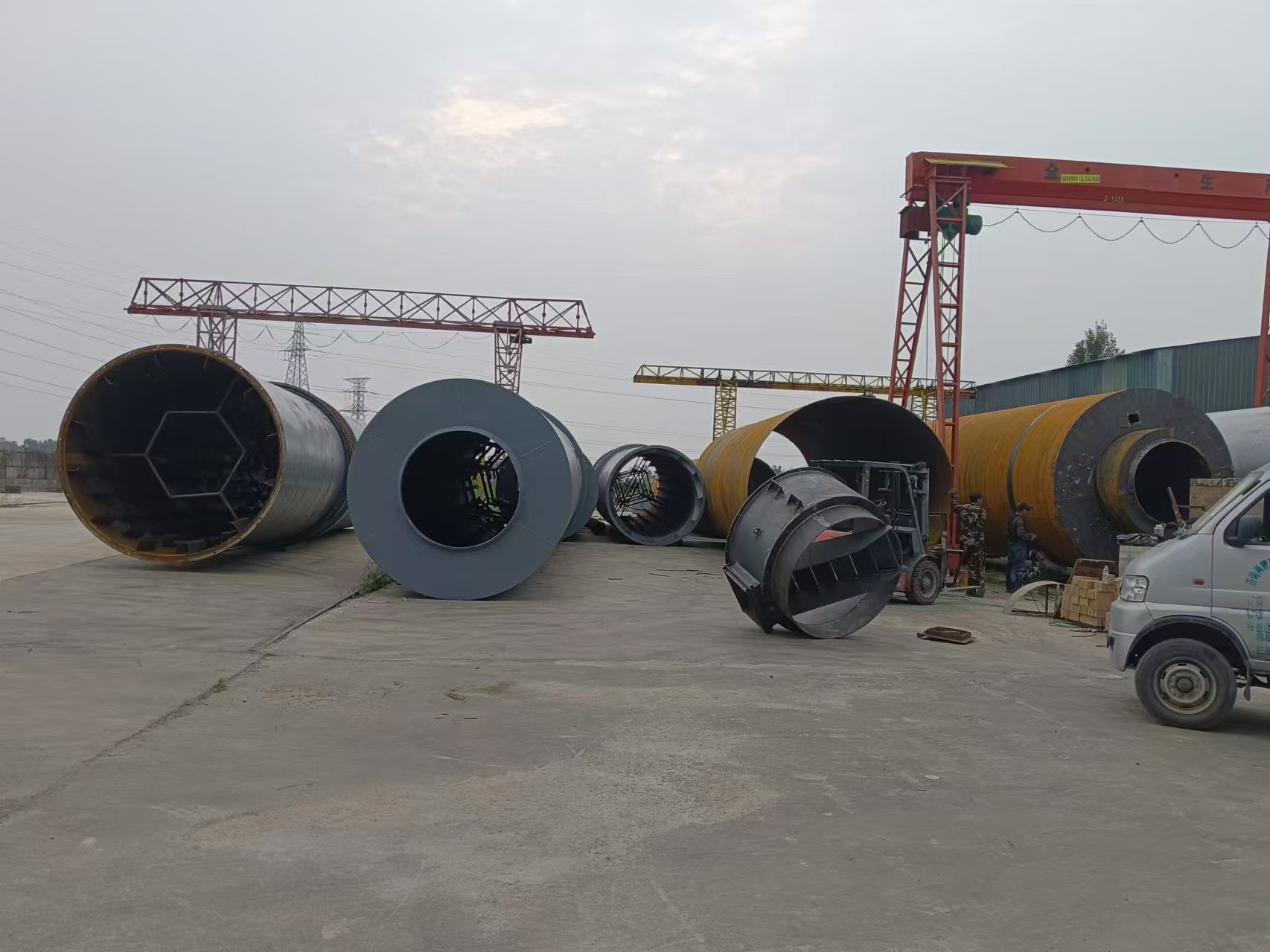

Equipment Configuration

A drum dryer alone cannot operate. Generally, it also requires a heat source (such as a hot air furnace), fans, a shakelong, and sometimes dust removal equipment.

Component Composition

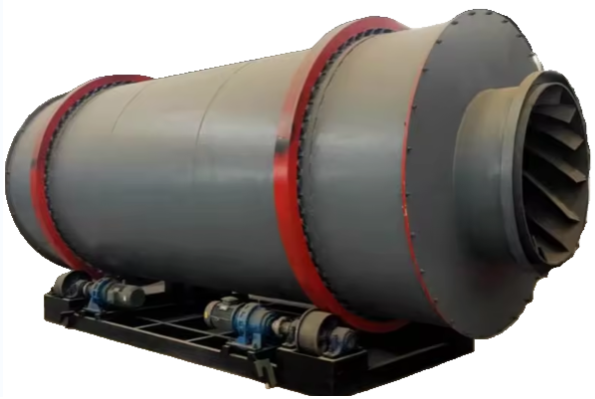

The drum dryer itself is composed of a cylinder, an inlet, an outlet, a toothed ring, and an aperture.

Product features

Parameter

Type | Model | Configuration | Evaporation(T/H) |

Single-cylinder dryer | HYHGφ1.5-12m | Main machine(7.5kw);Fan(15kw);Shaklon(φ1400);Electric control cabinet; | 0.5-0.75 |

HYHGφ1.5-15m | Main machine(11kw);Fan(18.5kw);Shaklon(φ1500);Electric control cabinet; | 0.5-0.75 | |

HYHGφ1.6-18m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 0.7-1 | |

HYHGφ1.8-15m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 1-1.3 | |

HYHGφ1.8-18m | Main machine(15kw);Fan(22kw);Shaklon(φ1600);Electric control cabinet; | 1-1.3 | |

HYHGφ2.0-20m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.4-2.0 | |

HYHGφ2.0-24m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.4-2.0 | |

HYHGφ2.2-24m | Main machine(18.5kw);Fan(30kw);Shaklon(φ1800);Electric control cabinet; | 1.7-2.5 | |

HYHGφ2.4-24m | Main machine(22kw);Fan(37kw);Shaklon(2-φ1500);Electric control cabinet; | 2.2-3 | |

HYHGφ2.8-24m | Main machine(30kw);Fan(55kw);Shaklon(4-φ1200);Electric control cabinet; | 2.5-3.6 | |

HYHGφ2.2-8-Ⅲ | Main machine(12kw);Fan(45kw);Shaklon(2-φ1200);Electric control cabinet; | 1.3-1.8 | |

HYHGφ2.4-9-Ⅲ | Main machine(12kw);Fan(45kw);Shaklon(2-φ1200);Electric control cabinet; | 1.6-2.5 | |

HYHGφ2.6-12-Ⅲ | Main machine(22kw);Fan(55kw);Shaklon(2-φ1400);Electric control cabinet; | 2.0-2.8 | |

HYHGφ2.8-12-Ⅲ | Main machine(22kw);Fan(55kw);Shaklon(2-φ1400);Electric control cabinet; | 2.1-3.0 | |

HYHGφ3.0-12-Ⅲ | Main machine(30kw);Fan(75kw);Shaklon(2-φ1500);Electric control cabinet; | 2.4-3.5 | |

HYHGφ3.2-12-Ⅲ | Main machine(30kw);Fan(90kw);Shaklon(2-φ1500);Electric control cabinet; | 3.0-5.0 |

Company Profile

The company is dedicated to cultivating lasting customer relationships. By virtue of high - grade products and assiduous dedication, we have been part of and witnessed the evolution of many of our customers. We are firmly of the opinion that there is no market without quality and no reputation without service. Quality and efficiency are the foundation for an enterprise to make its mark, and service and reputation are the keys to its prosperity.