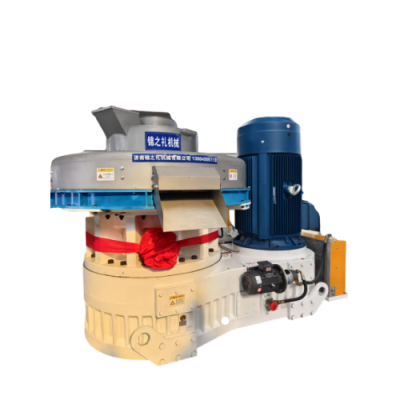

Wood Pellet Machine for Sale

High Production Efficiency

The direct link between the motor and the reducer's gearbox boosts kinetic energy conversion, which significantly enhances production efficiency, leading to more output in less time.

Long Service Life

Using a three - stage gear reducer increases load capacity. The press wheel now has a super wear - resistant alloy welding process instead of surface carburization. This not only extends the press wheel's life but also better protects the mold, cutting down on replacements and maintenance

Smooth Operation

The reducer's gearbox has a lubrication and cooling system. It can cool the lubricating oil without stopping the machine, ensuring smooth running and minimizing vibrations during operation.

Durable

The new toggle system with external rotary parts solves the issue of high - temperature steam erosion. The molds, made of wear - resistant stainless steel and vacuum - furnace quenched, have uniform hardness. They are highly wear - resistant and less likely to break, ensuring long - term reliable use in tough conditions.

Product features

1.The two-stage gear reducer enhances the load-bearing capacity. The forming roller adopts a high-strength ceramic coating process instead of the previous heat treatment method,

which extends the forming roller's service life and provides more reliable protection for the die.

2.The gearbox is equipped with an integrated lubrication and heat dissipation system. It can efficiently cool the lubricant without stopping the machine, ensuring stable operation.

3.The new linkage mechanism, with external rotating parts, overcomes the problem of corrosion caused by high humidity air, ensuring higher reliability.

4.The dies are made of anti-corrosion alloy steel and undergo salt bath quenching, resulting in uniform hardness and excellent anti-corrosion performance without cracking.

5..The power unit is directly connected to the transmission case of the reducer, which improves the energy utilization rate and speeds up the overall production pace 6.The pressing plate uses a wear-resistant composite material bonding process instead of the previous surface hardening treatment. This design extends the pressing plate's lifespan and better protects the mold.

Parameter

Category | Model | Power(KW) | Pellet size(mm) | Output(t/h) | Overall Dimension(mm) | Machine Weight(T) |

Vertical ring mould | JL560 | 132/160 | 6-12 | 1.5-2 | 2200*1280*1640 | 5T-5.5T |

JL2-850 | 250 | 6-12 | 3.0-4.0 | 2800*1720*2130 | 10.7T | |

JL2-850 | 280/315 | 6-12 | 4.0-5.0 | 2800*1720*2130 | 13.5T |

Company Profile

The company is committed to forging enduring customer connections. By offering top - notch products and showing meticulous dedication, we have accompanied and observed the development of numerous customers. We are convinced that quality paves the way to market presence and service builds a good reputation. Quality and efficiency are the cornerstones for an enterprise to gain a firm footing, while service and reputation are the catalysts for its advancement.