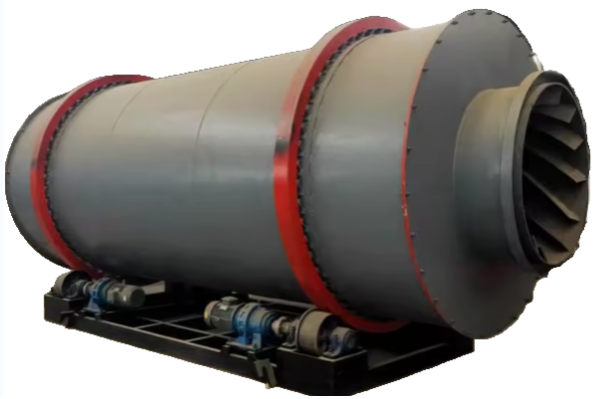

Industrial Three-drum dryer

High drying capacity: It has the ability to process a large amount of wet materials, thus boosting work efficiency.

Stable operation: The equipment operates steadily, which decreases the failure rate and guarantees continuous operation.

Low energy consumption: It saves energy and cuts down production costs.

Easy operation: The operation process is simplified, making it simple to operate and maintain.

High output: With high production efficiency, it can satisfy the requirements of large - scale production.

Application and Function

Industrial Rotary Dryer series products are mainly used for drying powdery, granular, small lumps and other wet materials.Widely used in energy, fertiliser, chemical and pharmaceutical industries.

Usage in Biomass GranulationIn the biomass granulation process, if the raw material moisture does not meet the granulation requirements, it needs to be dried.The three - drum dryer is a widely used drying device. It has the capacity to dry various materials such as wood chips, straw, and rice. This equipment is characterized by its simplicity in operation and stable performance during operation.

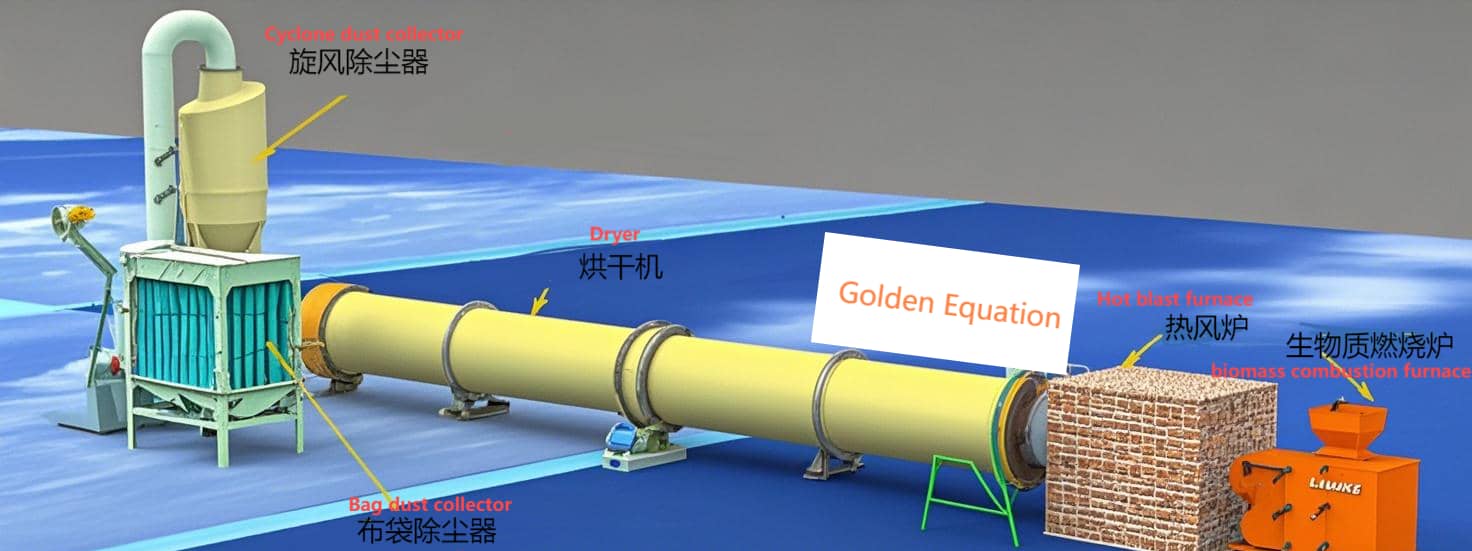

Component Composition

The drum dryer has key parts. The cylinder is where drying occurs, with an inlet for wet materials and an outlet for dry ones. A toothed ring ensures smooth cylinder rotation, and there's an aperture for functions like air/material flow control.

A drum dryer can't work alone. It needs a heat source like a hot - blast stove, a fan to blow hot air, and a cyclone separator (Shakelong) to separate gas from solids. Often, dust - removal equipment is added for environmental protection.

This dryer is widely used for drying biomass such as wood chips, straw, rice husks, and peanut shells. Drying makes these materials suitable for uses like biomass fuel production or feed processing.

Company Profile

Series of products are: wood pellet machine, straw pellet machine, biomass pellet machine, sludge briquetting machine, airflow, drum series drying equipment; cutting, crushing series of equipment, and other ancillary cooling equipment, screening equipment, packaging equipment, conveying equipment, such as a full set of biomass pellet production line equipment. The company's technical personnel according to the different needs of customers and customer plant space for customized configuration and design.