Hydraulic Bunker

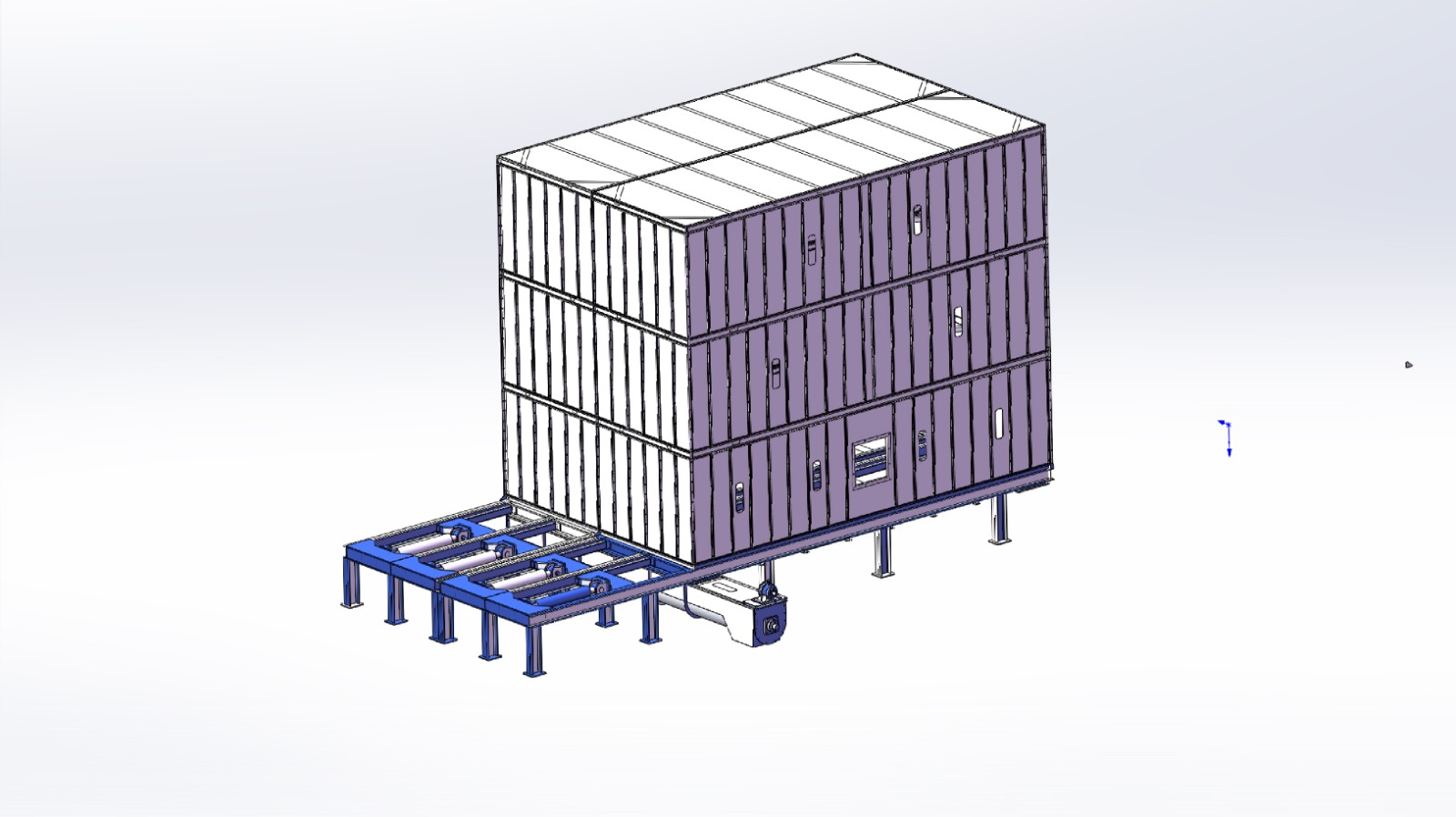

In the production process of the hydraulic silo, we have selected a split modular structure design to facilitate the transportation and installation of the equipment.

Each module is laser cut and punched to ensure the smooth progress of the equipment, manufacturing accuracy and installation.

The main frame is made of galvanized sheet bending, which is much stronger than the old process iron plate welding, and this material is not easy to corrode and durable.

Hydraulic Bunker Product Introduction

In the manufacturing process of the Hydraulic Bunker, a split modular structure design is adopted. This design not only significantly simplifies the transportation and installation of the equipment but also embodies a high - level of engineering sophistication. Each module is fabricated through laser - cutting for blanking and punching operations. This advanced manufacturing technique ensures the equipment's exceptional manufacturing precision, thereby guaranteeing a seamless and efficient installation process.

The main frame of the Hydraulic Bunker is crafted from galvanized sheets through a bending process. Compared to traditional iron - plate welding methods, this construction approach offers a substantial increase in structural strength. Additionally, the galvanized sheet material exhibits remarkable corrosion - resistance properties, endowing the equipment with enhanced durability and a longer service life.

The Hydraulic Bunker is a comprehensively designed system, primarily composed of a gantry, a sliding main beam, movable material - dialing wings, fixed material - dialing wings, hydraulic cylinders, a hydraulic station, a screw conveyor for discharging, and the bunker body. By virtue of its sealed material - storage design, the Hydraulic Bunker effectively addresses the issues associated with open - air material storage. It mitigates the environmental pollution and operational disruptions caused by dust, and reduces the reliance on forklifts and manual material handling, resulting in significant cost savings. Moreover, an explosion - proof vent is strategically installed on the bunker's roof. This safety feature serves as a crucial safeguard, effectively minimizing the risk of dust - related explosions and ensuring the overall safety of the operation.

Hydraulic Bunker Product Parameters | ||||||||

Volume Range (m³) | Specification | Overall Dimensions (m) | Total Volume (m³) | Power (kw) | Output | Customer - supplied Embedded Materials | ||

<100 | One - station Two - cylinder | 2.5x6x3.58 | 53 | 7.5 | 1-3T | 200*200Hsteel | Iron Plate Dimensions: | Ground Screw Bolt Specification |

One - station Two - cylinder | 2.5x6x2.58 | 38 | 7.5 | 42m | 3m | Φ20*220 | ||

One - station Two - cylinder | 2.5x6x4.74 | 71 | 7.5 | 2*20mm thick | ||||

100~200 | Two - stations Four - cylinder | 5x8x2.58 | 103 | 11*2 | 4-10T | |||

Two - stations Four - cylinder | 5x8x3.58 | 143 | 11*2 | 70m | 3m | Φ20*220 | ||

Two - stations Four - cylinder | 5x8x4.74 | 189 | 11*2 | 2*20mm thick | ||||

200~300 | Two - stations Four - cylinder | 5x8x5.74 | 229 | 11*2 | ||||

Remarks: The above specifications are the parameters of the hydraulic warehouse, excluding the customer's own steel frame and foundation embedded parts, excluding the dragon | ||||||||

Diverse Application Scenarios

Mining Industry: In mining operations, large quantities of minerals such as coal, iron ore, and copper ore need to be stored and transported. The Hydraulic Bunker can be used to store these minerals in a sealed environment. This prevents dust from spreading in the mining area, which is not only beneficial for environmental protection but also reduces the risk of respiratory diseases among miners. The efficient discharging system of the bunker, like the screw conveyor, can quickly transfer the minerals to the subsequent processing equipment, streamlining the entire mining process.

Power Plants: Coal - fired power plants handle vast amounts of coal daily. The Hydraulic Bunker provides a reliable storage solution. It ensures that the coal is stored securely, protecting it from the elements and reducing the loss of calorific value due to weathering. During the coal - feeding process, the hydraulic components can precisely control the amount of coal discharged, optimizing the combustion efficiency of the boiler and improving the overall power - generation efficiency.

Agricultural Granaries: For storing grains like wheat, corn, and rice, the Hydraulic Bunker offers a dust - free and pest - resistant storage environment. The sealed structure keeps out insects and rodents, protecting the stored grains from damage. In addition, the bunker's design allows for easy loading and unloading, facilitating the efficient management of agricultural products during harvest seasons and throughout the storage period.

Construction Material Factories: Factories producing construction materials such as cement, sand, and gravel can benefit greatly from the Hydraulic Bunker. Cement, in particular, is highly prone to dust pollution. The bunker's sealed storage and dust - suppression features ensure a clean working environment. When it comes to the supply of materials for construction projects, the bunker can accurately control the discharge volume, meeting the precise material requirements of different construction tasks.