Product Description of Rotary Cutting Crusher

1. General Overview

The Rotary Cutting Crusher is a high - performance device designed to meet diverse material crushing demands, excelling in processing agricultural and biomass materials. Comprising a base, gear drive, and rotary box, it can crush straw into small particles like a professional wood crusher.

2. Crushing Range

It can handle a wide variety of fibrous materials such as thatch and corn stalks, grinding them into uniform powder. This makes it a top choice for crop straw - related industries, crucial for straw - based fuel and biomass power generation.3. Feeding System

With feeding port diameters of 2000mm, 2500mm, and 3000mm, it easily accepts piled or bundled materials. Standing about 1 meter high, its intermittent feeding enables continuous crushing. The rotating feeding port pushes materials to the rotor, and crushed materials are ejected directly, reducing the need for extra conveyors.

4. Core Components

Disc cutters and hammer blades on the rotor are key. Cutters initially break down materials, and hammer blades further crush them. Made of high - quality alloy, cutters are hard and wear - resistant, while hammer blades have carbide - welded edges for longer life.

5. Application Fields

Widely used in charcoal, straw coal, and biomass pellet plants, it ensures efficient production. It's also vital in agricultural waste recycling and biomass power generation, promoting sustainable development.

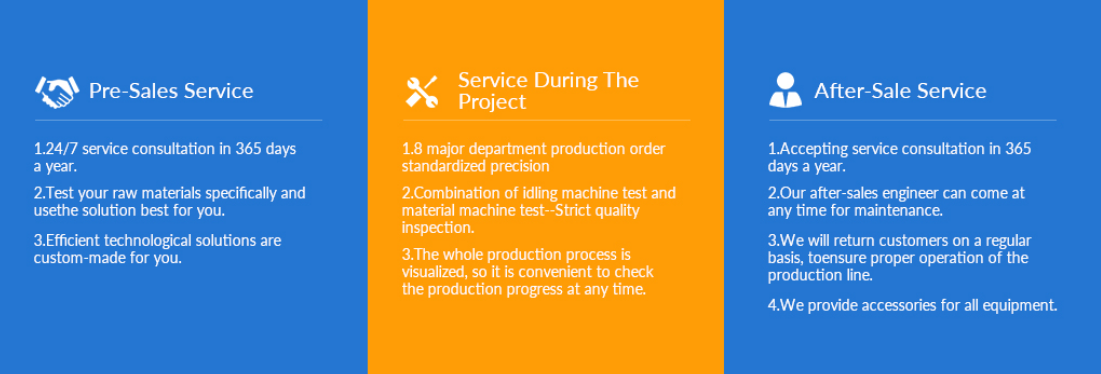

6. After - sales Service

We provide free technical support, a one - year warranty (excluding human - caused damage and vulnerable parts), and lifetime maintenance (auxiliary equipment not included, with charges for some replacements), guaranteeing smooth operation.

Company Profile

Our company offers a diverse range of products. This includes wood pellet machines, straw pellet machines, biomass pellet machines, and sludge briquetting machines. Additionally, we provide airflow and drum series drying equipment, as well as cutting and crushing series equipment. Moreover, we supply various ancillary equipment such as cooling devices, screening machines, packaging machines, and conveying systems, forming a complete set of biomass pellet production line equipment.

Our company's technical experts customize configurations and designs based on customers' specific requirements and the available space in their plants.