Product Introduction

The High efficiency grinder series single - shaft crusher is a standardized product manufactured by our factory. It is capable of crushing fibrous materials like small wood chips, shavings, and wheat straw that have already been roughly crushed. Additionally, it can crush granular feed raw materials such as corn.

This series of crushers features a steel - plate welding construction. The motor and the crusher rotor are mounted on a common base and are directly connected and driven via a drum - type gear coupling. The rotor has been calibrated for dynamic balance and is able to operate in both forward and reverse rotations. The feeding port is located at the top of the crusher and can be paired with a variety of feeding mechanisms. This equipment can be extensively applied in the biomass energy and feed processing industries.

Main Technical Parameters and Performance Indicators

(1) Main Technical Parameters

Model and Specification | 65 - 130 | 1000 - 1600 | 1200 - 1300 |

Spindle Speed (r/min) | 2900 | 1800 | 1450 |

Number of Screen Plates (pieces) | 96 | 132 | 116 |

(2) Performance Indicators

Model and Specification | 65 - 130 | 1000 - 1600 | 1200 - 1300 |

Power (kW) | 132kw | 250kw | 315kw |

Output (tons/hour) | 4 - 6 | 8 - 10 | 12 - 14 |

Note: The above indicators must meet the following conditions:

①The raw material variety is 50×50×5mm (thick) wood chips with a moisture content of less than 15%, and the diameter of the screen plate holes of the crusher is φ12 - φ16 mm;

②For crude fiber, the above output will fluctuate up and down with the size of the screen holes and the moisture content of the material.

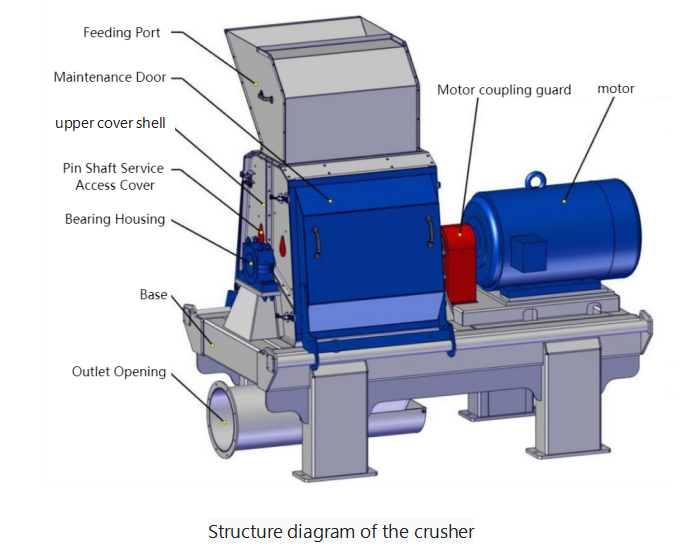

Main Structure and Working Process

(1) Main Structure (see the figure below)

1. Base: It plays a role in connecting and supporting various components of the crusher, making them form an integral whole. The crushed materials are sucked out by the wind from the side of the base.

2. Rotor: It consists of parts such as the main shaft, hammer frame plate, pin shaft, hammer pieces, and bearings. It is the main moving part of the crusher. The rotor rotates at a high speed. After assembly, dynamic balance inspection is carried out without installing the pin shaft and hammer pieces.

3. Maintenance Door: The maintenance door needs to be opened when replacing the screen plate and hammer pieces. The screen plate is pressed by a special pressing mechanism. When the crusher is working, the maintenance door is locked by a quick - acting fixture to ensure that it cannot be opened when the rotor is rotating.

4. Upper Housing: There is a feeding port at the upper part, and it is connected to the base at the lower part. Screen plates are installed on both sides respectively, and together with the rotor, they form a crushing chamber. The materials are crushed in the crushing chamber.

(2) Working Principle

The materials to be crushed enter the crushing chamber through the feeding mechanism matched with this machine from the top feeding port. Under the impact of the high - speed rotating hammer pieces and the friction of the screen plates, the materials are gradually crushed. Under the action of centrifugal force and air flow, they pass through the screen holes and are sucked out by the wind from the side of the base.

Company Profile

Our company focuses on fostering long - standing customer relationships. Through providing excellent products and demonstrating scrupulous commitment, we have accompanied and witnessed the expansion of a large number of our customers. We truly believe that quality is the sole way to gain a market share and service is the only means to build a reputation. Quality and efficiency are the basis for an enterprise to stand firm, and service and reputation are the keys to its growth.