Deciprocating Grate Boiler for Sale

1. Wide Range of Applications

Applied in boilers, furnaces, kitchen gear, etc., the Biomass Pellet Burner meets diverse industries' heat needs by integrating with various equipment.

2. Smart & Easy to Use

It features auto - feeding, discharging, ignition, and temperature control, running 24/7 unattended to cut labor costs.

3. Cost - effective

Low investment and operation costs make it a money - saving choice for businesses.

4. Efficient Combustion

Variable frequency tech adjusts combustion power, and customizable combustion types and controls offer flexibility

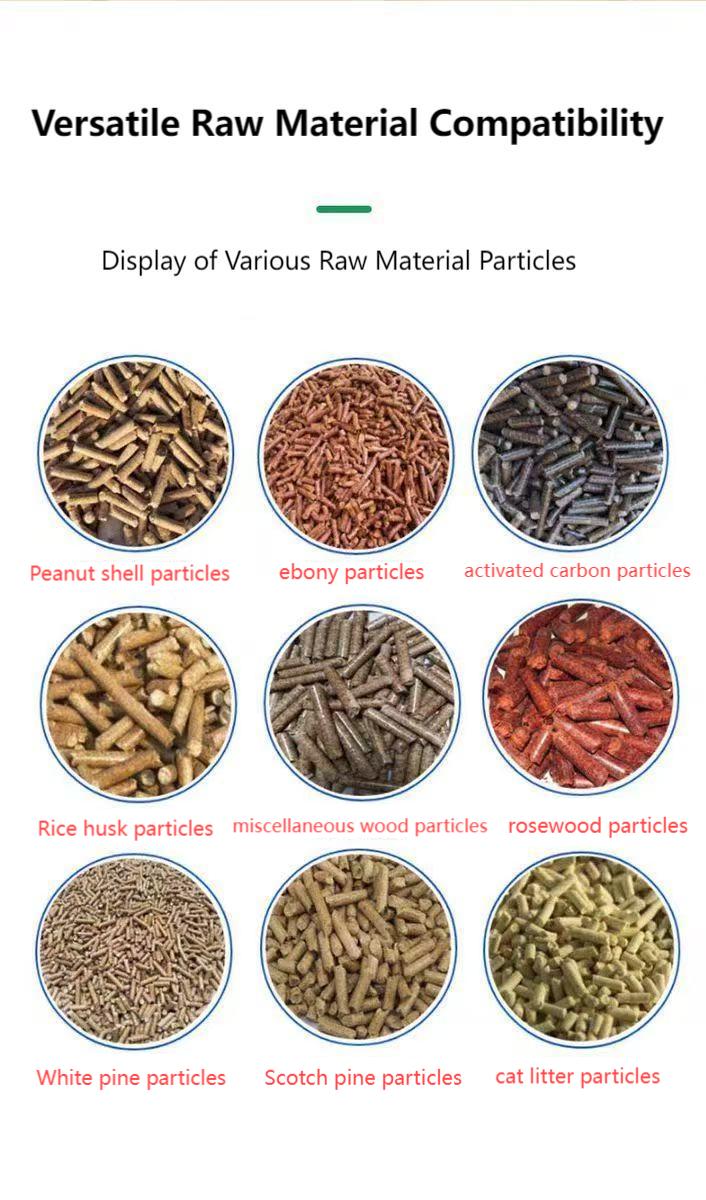

Biomass burners can utilize a diverse range of fuel sources, which are as follows:

Agricultural Waste

Materials such as corn stalks, wheat straws, rice straws, and other types of crop residues are abundant and inexpensive. These agricultural by - products offer a readily available and cost - effective option for biomass burners.

Forestry Waste

Sawdust, wood shavings, branches, and tree bark are typical examples. Generally, these are the remnants from wood processing activities and serve as excellent biomass fuel sources.

Processing Waste

Substances like rice husks, peanut shells, and bagasse fall into this category. Generated by food processing facilities and woodworking plants, they make for highly suitable biomass fuels.

Energy Crops

These are crops cultivated specifically for the purpose of combustion to generate electricity or heat. Sweet sorghum and switchgrass are prime examples within this classification.

Company Profile

Our Commitment to Your Project

At Jian Golden Equation Machinery Manufacturing Co., Ltd. ,we understand that a successful project hinges not only on high - quality products but also on comprehensive and reliable services. That's why we offer a full - spectrum service package tailored to support you at every stage of your project.

Pre - sales Service

Our pre - sales service is designed to ensure you start your project with confidence. We provide 24/7 service consultation throughout the year, ready to answer any questions you may have. We'll also conduct specific tests on your raw materials, helping you choose the most suitable solution for your needs. Additionally, we'll customize efficient technological solutions for you, ensuring that your project gets off to the best possible start.

Service During the Project

During the project implementation, we maintain strict production standards. Our eight major departments follow a standardized and precise production order to guarantee the quality of our products. We conduct both idle machine tests and material machine tests, subjecting each product to strict quality inspections. Moreover, we've made the entire production process visualized, allowing you to conveniently monitor the production progress at any time.

After - sales Service

Our commitment doesn't end with the delivery of our products. We offer 365 - day service consultation for after - sales support. Our after - sales engineers are on standby, ready to arrive at your site for maintenance whenever needed. We also conduct regular customer follow - ups to ensure that your production line is operating smoothly. To further support you, we provide accessories for all our equipment, ensuring long - term and trouble - free operation.

With our all - encompassing service, we aim to be your trusted partner, helping you achieve success in your projects.