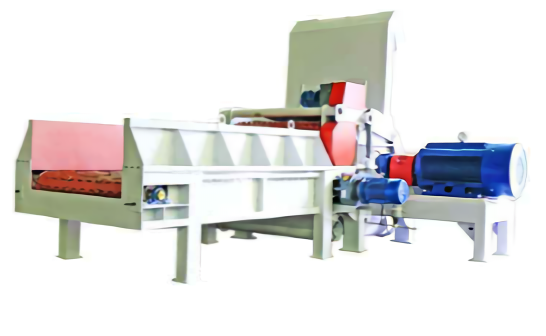

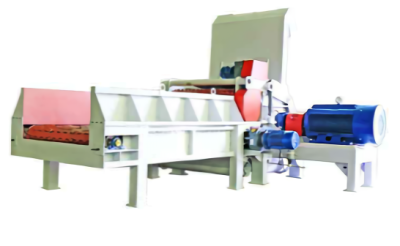

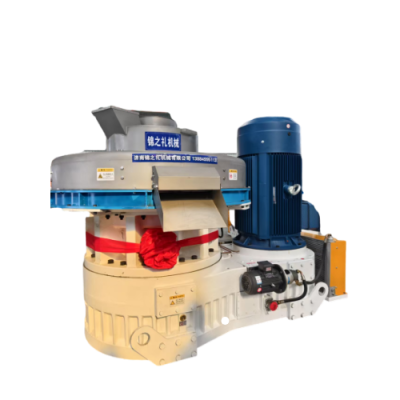

Integrated Crushing and Powdering Machine

Advantages of the feeding chain plate design

The single - step stamped feeding chain plate has enhanced rigidity, is more robust and durable, and can better withstand harsh working conditions.

Advantages of the current detection system and feeding control

The current detection system automatically pauses and resumes feeding based on processing ability, reducing material blockages and machine malfunctions.

Advantages of the hydraulic motor in the feeding system

The internal hydraulic motor in the feeding system prevents leakage, resists blockages, has a long service life, quick start - up, and high torque. It can handle blockages and resume feeding after a delay.

Advantages of the heavy - hammer - type knives

Heavy - hammer - type blades made of wear - resistant materials are easily replaceable, improving crushing efficiency and fineness.

Advantages of the two - stage metal removal process

The two - stage metal removal process expels heavier metals and efficiently eliminates non - magnetic metals, ensuring operational safety.

Integrated Crushing and Powdering Machine:

Our Integrated Crushing and Powdering Machine is a high - tech device for diverse industrial demands.

Material Processing Flexibility

It can handle metal - containing materials like construction templates, wooden pallets, and factory scraps. It enables one - step crushing and pulverizing of trees, timbers, etc., directly into fuel pellet raw materials. Compared to the old two - machine setup, it simplifies the process and cuts costs.

Diverse Application Scenarios

Biomass Energy Industry:

In the biomass energy sector, the machine plays a crucial role. It can process biomass materials such as straw, wood chips, and corn cobs. By crushing and pulverizing these materials, they can be transformed into a suitable form for biomass power generation or the production of biofuels. This not only promotes the utilization of renewable energy but also helps to reduce the reliance on traditional fossil fuels.

Agricultural Waste Treatment

Farmers and agricultural processing facilities frequently struggle with the disposal of agricultural waste, including crop stalks and husks. Our integrated machine offers an efficient solution for processing such waste. Once crushed and powdered, these materials can be utilized for composting, enhancing soil quality, or serving as bedding for livestock. This not only transforms waste into valuable resources but also promotes the sustainable development of agricultural production.

Advanced Operation Features:

Flexible & Durable:The machine can be frequently started and moves smoothly forward and backward. With a long lifespan, sensitive start - up, and high torque, it adapts well to different working conditions, reducing breakdowns.

Powerful & Replaceable Knives:Equipped with heavy - hammer - type, super - wear - resistant knives, it's easy to replace them. This design improves crushing efficiency and material processing, handling various materials with ease.

Model | POWER(KW) | Output(T/H) |

TR-C72140 | 200+5.5+5.5 +7.5+1.5+2.2 | 3-5 |

TR-C72140 | 250+5.5+5.5 +7.5+1.5+2.2 | 4-6 |

TR-C90150 | 315+18.5+0.13 | 6-10 |

TR-C90150 | 200*2+18.5+ 0.13 | 7-12 |

TR-C90150 | 250*2+18.5+ 0.13 | 8-14 |

TR-C90150 | 315*2+18.5+ 0.13 | 10-16 |

Transparent Pricing:

We know cost matters. When investing in our machine, expect clear pricing. Factors like capacity, material quality, extra features, and brand reputation determine the price. Our simple structure helps you compare and make a smart buying decision.

Advanced Tech & Robust Build:

The machine uses advanced technology for smooth operation. Its innovative crushing mechanisms handle diverse materials easily. Built with quality materials, it's durable in harsh conditions, reducing maintenance and extending service life.

Comprehensive After - sales:

Reliable Service:

In addition to its outstanding performance, we offer comprehensive after - sales support.

Free Technical Support:

We provide free technical support services to our customers. Whether you encounter problems during machine installation, commissioning, operation, or routine maintenance, you can contact our professional technical team at any time. We will do our utmost to answer your questions and offer assistance.

One - year Warranty for the Whole Machine:

We offer a one - year warranty for the integrated crushing and powdering machine. During this one - year period, if any malfunctions occur due to quality issues, we will provide free repair services and replace faulty parts. However, it should be noted that this warranty does not cover auxiliary equipment, man - made damage, and the replacement of wearing parts.

Lifelong Maintenance (Excluding Auxiliary Equipment, Man - made Damage, and Replacement of Wearing Parts):

We provide lifelong maintenance services throughout the product's lifespan. Even after the warranty period, when there are problems with your machine, our technicians will still provide professional repair services. Nevertheless, for faults in auxiliary equipment, damage caused by human factors, and the replacement of wearing parts during normal use, the customer shall bear the corresponding costs. We will ensure that your machine is always in good operating condition with reasonable prices and efficient services.

Company Profile

Series of products are: wood pellet machine, straw pellet machine, biomass pellet machine, sludge briquetting machine, airflow, drum series drying equipment; cutting, crushing series of equipment, and other ancillary cooling equipment, screening equipment, packaging equipment, conveying equipment, such as a full set of biomass pellet production line equipment. The company's technical personnel according to the different needs of customers and customer plant space for customized configuration and design.