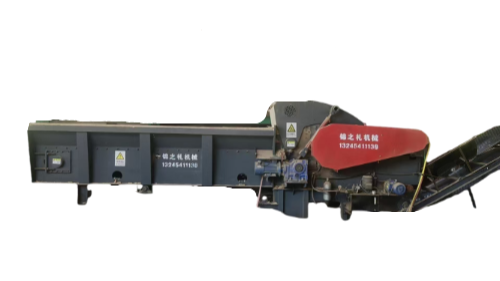

Innovative Chain Plate Design

Our chain plate incorporates an upper welded link bar, effectively eliminating the problem where a single - point break could cause the entire plate to fail. The lower layer features a wear - resistant track, enhancing elasticity, reducing wear, and extending the plate's service life.

Quality - Guaranteed Components

We exclusively utilize brand - new motors, reducers, and electronic control components. To ensure reliability, the motors come with a 2 - year warranty, providing peace of mind for our customers.

Robust Roller and User - Friendly Design

The lower roller of the equipment is self - welded with a solid, one - piece shaft, which prevents deformation and ensures smooth operation. Thanks to the special slide knife design, screen replacement can be easily carried out without the need to open the forced feeding system, making maintenance more convenient and efficient.

![Integrated Crusher Integrated Crusher]()

Chain Plate with Wear - Resistant Runway: The chain plate's high - wear - resistant runway design minimizes wear, extends the chain plate's service life, and enhances the equipment's stability.

New Motor and Reducer Setup: The new configuration of the motor and reducer, along with the warranty policy, guarantees the long - term reliability of the equipment.

Self - Welded Rollers: The self - welded rollers prevent unnecessary production stoppages, thereby increasing production efficiency.

Safety - Ensuring Hydraulic Components: The high - standard hydraulic oil top and insurance lever ensure safety during hammer head replacement and equipment overhaul.

High - Speed Knife Roller: The equipment's knife roller can reach a speed of 888 - 926 rpm, which is higher than the 600 rpm of ordinary manufacturers. This increases the crushing strength and effectively reduces time and operating costs.

Segmental Conveying Design: The segmented conveying design facilitates discharging, avoiding the inconvenience caused by a single motor and reducer, and further boosting production efficiency.

![Integrated Crusher Integrated Crusher]()

Parameter

Model | Main power | Feeder motor power | Feed opening size | Knife roller diameter | YG8 Alloy crushing hammer |

1250-500 | 110 | 7.5+5.5 | 1250*500 | 800 | 24 |

1300-500 | 132 | 5.5+7.5 | 1300*500 | 800 | 24 |

1400-500 | 160 | 11+7.5 | 1400*500 | 800 | 24 |

1450-600 | 200 | 11+7.5 | 1450*600 | 900 | 24/28 |

1450-800 | 200/250 | 15+11/11+11 | 1450*800 | 1050 | 24/28 |

1600-500 | 160 | 11+7.5 | 1600*500 | 800 | 28/32 |

1650-600 | 200-220 | 11+7.5 | 1650*600 | 900 | 28/32 |

1650-800 | 220-280 | 15+11 | 1650*800 | 1050 | 28/32 |

1000-500 | 110/132 | 5.5+4/5.5+5.5 | 1000*500 | 800 | 18 |

Crusher series is a professional equipment for producing wood chips, which is widely used in biomass energy industry for raw material production and fuel storage in biomass power plants. |

![Integrated Crusher Integrated Crusher]()

![Integrated Crusher .jpg Integrated Crusher .jpg]()

![Integrated Crusher .jpg Integrated Crusher .jpg]()

![Integrated Crusher .jpg Integrated Crusher .jpg]()

![Integrated Crusher.jpg Integrated Crusher.jpg]()

![Integrated Crusher .jpg Integrated Crusher .jpg]()

![Integrated Crusher .jpg Integrated Crusher .jpg]()

Established in 2019, Jinan Jinfangcheng Machinery Manufacturing Co., Ltd. is a production-oriented enterprise. Situated at No. 10, Jinshan West Road, Taohuashan Industrial Park, Xiuhui Town, Zhangqiu District, Jinan City, Shandong Province, the company combines the design, development, and manufacturing of mechanical equipment with international trade.

Mainly serving industries like environmental protection, low - carbon projects, biomass energy, and urban - rural environmental development, the company offers a diverse product portfolio. This includes biomass compression molding equipment, organic fertilizer machinery, urban and rural waste treatment systems, and environmental protection dust removal equipment. These products have gained wide recognition and high praise both in the domestic market and around the world within the relevant industries.

![Comprehensive Crusher.jpg Comprehensive Crusher.jpg]()